What is the difference between steel cable and wire rope?

Did you know the global steel wire rope market was worth $11.9 billion in 2020? It's expected to grow by 8% each year, reaching $17.5 billion by 2028. This rapid growth shows how much we rely on steel cables and wire ropes in industries like oil and gas, construction, and marine fishing.

But what's the difference between these two materials? Knowing the technical details and uses of steel cable vs wire rope can greatly affect project success and safety.

Steel cables have smaller diameters, usually under 3/8 inch. They are made to be flexible, perfect for precise tasks like in aviation. Wire ropes, on the other hand, are built for bigger tasks. They come in various finishes like bright, galvanized, or stainless steel, each suited for different environments.

It's important to understand the materials' composition, including how they are made. Steel cables often use 7x7 or 7x19 configurations. Wire ropes have more complex designs, affecting their strength and flexibility. These differences are key to choosing the right material for a project.

Key Takeaways:

- The global steel wire rope market is projected to grow by 8% annually, reaching $17.5 billion by 2028.

- Steel cables typically have smaller diameters (less than 3/8 inch) and are highly flexible, suitable for precise applications like aviation.

- Wire ropes support larger-scale operations with robust construction and vary in finishes including bright, galvanized, or stainless steel.

- Steel cables often use 7x7 or 7x19 configurations, whereas wire ropes have more complex strand and wire arrangements.

- Technical specifications and application environment are critical factors in the steel cable vs wire rope comparison.

Introduction to Steel Cable and Wire Rope

Steel cable and wire rope are key tools in many industries that we supply at Bishop Lifting. They work like machines, moving forces and energy for specific tasks. Over 200 years, they've changed a lot, thanks to new needs and tech.

What makes steel cable and wire rope different is their size. Wire rope is bigger than 3/8 inch, while smaller sizes are called cable or cords. They're used in everything from small tools to big bridges, showing their strength and flexibility.

Wire ropes are made of many metal wires wrapped around a core, usually carbon steel. They come in designs like 7x19 and 7x7. Their size and how they're made affect how flexible and tough they are.

The materials in wire ropes include stainless steel and galvanized carbon steel. Choosing the right material and design depends on strength, durability, and how well they resist wear and corrosion. It's also important to use the right hardware, like thimbles and clips, to keep the rope in good shape.

Knowing how these materials perform is key. Things like how they handle wear and bending are important. Rules from places like OSHA help make sure they're used safely and right.

In summary, steel cable and wire rope are vital in many areas. Their differences in how they're made and used show their importance. As they keep getting better, they'll keep helping industries grow and stay safe.

Structural Differences and Applications

It's important to know the differences between steel cable and wire rope. Each has its own strengths for different tasks. This makes them more effective in many settings.

Wire Rope Construction

Wire ropes are made of many wire strands twisted around a core. This design gives them great strength, flexibility, and resistance to wear. The wire arrangement can change, like 6x7, 6x19, or 7x19, affecting how they handle loads.

Because of this, wire ropes are perfect for heavy work in mining, construction, and at sea.

Steel Cable Features

Steel cables are made of thinner strands, making them more flexible than wire ropes. They often have a 7x7 or 3x7 design. This flexibility is great for moving things around, like in lifting gear and plane controls.

Material and Finish

The material and finish of steel cable and wire rope are key to their performance. Stainless steel wire rope is perfect for salty, wet places because it doesn't rust. Galvanized steel wire rope is cheaper and works well in many industrial settings.

Each type has its own benefits, ensuring they last long and work well in their specific roles.

In summary, the differences in construction, material, and features of steel cable and wire rope make them ideal for different tasks. Understanding these differences helps make the best choice for your needs.

What is the difference between steel cable and wire rope?

In the industrial world, knowing the steel cable wire rope comparison is key. Both steel cable and wire rope are used for heavy tasks. But they differ in size, how they're made, flexibility, and finish.

One big steel cable and wire rope contrast is their size. Steel cables have smaller strands, starting at .032 inches. Wire ropes start at 3/8 inches. This size difference affects their load capacity and use.

Steel cables are mostly 7×7 or 7×19, making them flexible and resistant to fatigue. This is good for small, precise jobs.

Looking at material and finish, there are clear differences. Steel cables are often galvanized or stainless steel, offering better resistance to wear and tear. Wire ropes can be bright, galvanized, or stainless steel, with stainless steel being the strongest. This variety makes wire ropes suitable for many industrial settings, like marine and mining.

Wire ropes come in many types, like Fiber Core (FC), Independent Wire Rope Core (IWRC), and Wire Strand Core (WSC). These affect their flexibility, load limits, and how they handle the environment. For example, a 6×19 wire rope balances flexibility and strength, making it versatile for many uses.

In summary, the steel cable wire rope comparison shows each has its own benefits. Steel cables are best for small, precise tasks needing flexibility. Wire ropes are stronger and better for heavy, complex jobs that need to withstand harsh environments.

Conclusion

Looking at steel cable vs wire rope shows us their unique uses. Steel cables are smaller and flexible, great for planes and some boats. Wire ropes, with their strong structure, are perfect for heavy tasks like building and factories.

Knowing the differences in structure and materials is key. For example, galvanized wire ropes are good for most places because they're zinc-coated. Stainless steel wire ropes are best for very tough environments because they don't rust easily. The design of the wire rope, like its core or pattern, also affects its strength and how long it lasts.

Choosing between steel cable and wire rope is important. You need to think about how much weight it can hold, the weather, how flexible it needs to be, and what the project requires. Getting advice from experts and buying from trusted suppliers like Bishop Lifting is a good idea. This way, you make sure you're meeting safety and quality standards. Knowing the differences between steel cable and wire rope helps you use them better in different situations.

Whether you need steel cable or wire rope for rigging, lifting, or as part of fall protection check out our website for in stock wire rope for sale online

FAQ

What is the difference between steel cable and wire rope?

Steel cables are smaller than 3/8 inch in diameter. They are good for flexible, lighter tasks. Wire rope, with larger diameters, is for heavy-duty jobs needing more strength.

Are steel cables and wire ropes interchangeable?

Though often called the same, they're not exactly the same. Steel cable is for flexible, lighter tasks. Wire rope is for heavy-duty jobs because of its strength.

How is wire rope constructed?

Wire rope is made by winding multiple wire strands around a core. This design varies to meet different needs, like strength and flexibility. It's great for tough jobs like mining and construction.

What are common steel cable configurations?

Steel cables come in 7x7 and 3x7 configurations. These offer a mix of flexibility and durability. They're used in things like exercise gear and small machines.

What materials are used in steel cables and wire ropes?

They're usually made from stainless steel or galvanized carbon steel. Stainless steel fights corrosion well, while galvanized steel is cheaper. The material choice affects how long they last and how well they perform.

Why is the diameter important in distinguishing steel cable from wire rope?

Diameter is key for choosing the right material. Steel cable's smaller size is better for lighter tasks. Wire rope's larger size and strength are needed for heavy tasks.

Can I use steel cable for suspension bridges?

No, steel cable is not right for suspension bridges. It's too small and can't handle the load. Wire rope, with its larger size and strength, is better for such big jobs.

How should I choose between steel cable and wire rope for my project?

Think about what your project needs. Look at load capacity, flexibility, and how it will last. Talking to experts like Bishop Lifting and suppliers can help you choose wisely.

Ratchet vs. Lever Chain Binders: Which Is Better for Your Load?

Mar 2nd 2026

Lifting vs. Rigging Equipment: What’s the Difference (and What You Actually Need)?

Feb 24th 2026

The Complete Buyer’s Guide to Overhead Cranes

Feb 13th 2026

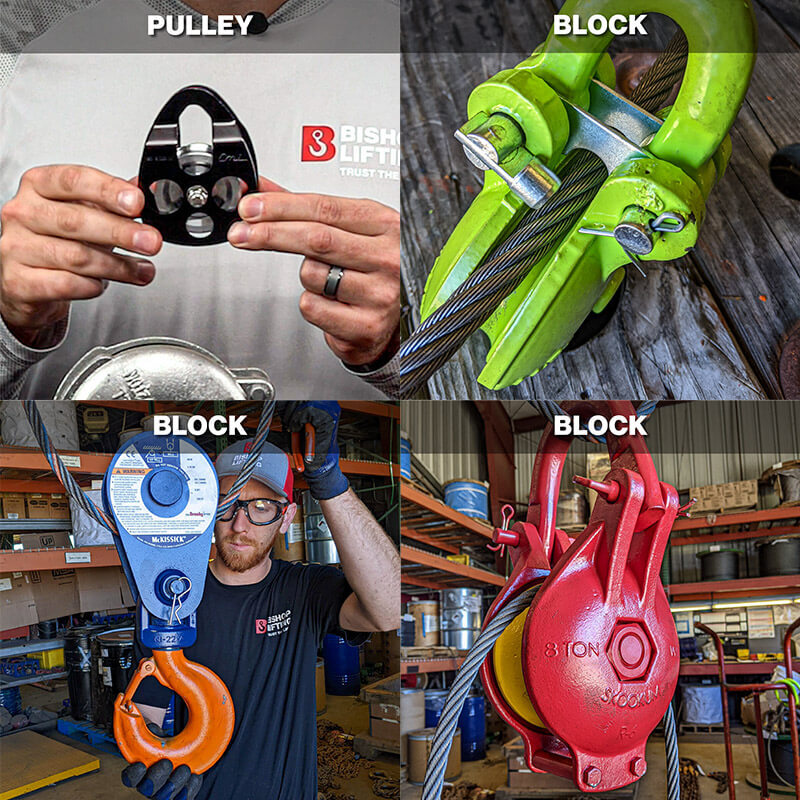

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026