The Complete Buyer’s Guide to Overhead Cranes

Feb 13th 2026

A practical, standards-minded guide for selecting an overhead crane system—and the hoist + rigging gear that makes it safe, efficient, and compliant.

Quick reality check (so this guide matches your audience):

Many teams use “overhead crane” to mean the complete bridge crane system (runway, bridge, trolley, controls) plus the items you buy most often—hoists, trolleys, slings, shackles, hooks, and below-the-hook devices. Lifting.com is especially strong on the equipment you spec, replace, and use every day (hoists + pullers, beam clamps + trolleys, rigging hardware, slings, spreader beams, and services like training/inspection). That’s exactly what this buyer’s guide emphasizes.

Need help sizing a crane/hoist package?

If you want a fast recommendation, jump to the checklist at the bottom and then request a quote from Lifting.com with your key specs.

What you’ll learn

1) Overhead crane basics (what you’re actually buying)

An overhead crane is a fixed, building-supported system that moves loads across a bay using a runway + bridge + trolley + hoist. If your team is comparing overhead vs. gantry style systems, this article is a helpful primer: What is the Difference Between Overhead and Gantry Cranes?

Common overhead crane configurations

- Top-running bridge crane: the bridge rides on rails on top of runway beams—common for higher capacities and heavy duty service.

- Underhung bridge crane: the bridge runs under the runway—often helpful when you need lighter capacities or more ceiling/structure constraints.

- Single girder vs. double girder: affects hook approach, lift height, span options, and duty cycle.

Buying tip:

The biggest mistakes happen when teams size only for capacity and ignore duty cycle, lift height, hook approach, and the rigging that connects the load.

2) How to size an overhead crane system

Use this as your sizing framework before you spec the hoist and day-to-day rigging.

A. Rated capacity (WLL) + headroom

- Capacity: include the weight of below-the-hook devices (spreader beams, lifting beams, clamps) plus slings and hardware—then add appropriate margin for real-world handling.

- Lift height + hook approach: determine whether you need a low-headroom hoist/trolley configuration.

B. Span + runway travel

- Map your bay: max span, clearances, and where you need full hook coverage.

- Plan for obstructions (HVAC, lighting, ductwork, mezzanines) early—retrofits cost more than doing it right up front.

C. Duty cycle + environment (the “profit lever”)

- Duty cycle: how many lifts per hour/day, typical load weight, and how “hard” your starts/stops are. This often drives component selection more than max capacity.

- Environment: heat, corrosion, washdown, outdoor exposure, and contaminants all change what finishes and maintenance practices you need.

Pro insight:

If production depends on your crane, prioritize uptime: spec for the real duty cycle, and standardize on rigging that reduces rework and improves load control.

3) How to choose the right hoist + trolley

For many buyers, the “overhead crane decision” becomes a hoist decision—because the hoist affects speed, control, headroom, and maintenance. If you want a deeper hoist explainer, here’s a helpful article: What Are Hoists Used For?

Hoist selection checklist

- Power: manual, electric, or pneumatic (match facility constraints and duty cycle).

- Lift media: chain vs. wire rope (depends on lift height, speed, and service class).

- Low headroom needs: if hook approach and lift height are tight, design around it now—not after install.

- Control: pendant vs. radio control and how fine your load positioning must be.

Trolley selection (how the hoist travels)

- Push trolleys: cost-effective for lighter use and shorter runs.

- Geared trolleys: more controlled positioning (especially under load).

- Beam clamps: when you need a secure attachment point on a beam flange for hoisting or temporary systems.

Shop the equipment that supports overhead crane work

These are the categories buyers most often spec, replace, and standardize across facilities to improve safety and uptime.

Electric and manual hoists, lever tools, and related lifting solutions—ideal for overhead crane hook blocks, maintenance lifts, and production handling where controlled vertical lift matters.

Beam clamps, push trolleys, and geared trolleys that help you travel and position loads smoothly—especially useful for monorails, maintenance systems, and supporting hoist installations.

Synthetic, wire rope, and chain slings for everyday overhead lifts. Dialing in the right sling type and angle is one of the fastest ways to reduce damage, improve control, and speed up rigging.

Shackles, hooks, master links, lifting points, turnbuckles, and more—critical connectors that control the load path between the crane hook and the lift. Standardizing hardware can simplify training and inspections.

When load stability matters, spreader beams can reduce sling angles, protect the load, and improve control—often increasing both safety and throughput for long, flexible, or delicate picks.

Davit cranes, capstan winches, and related solutions—ideal for maintenance lifting, marine/wastewater applications, and jobsite handling when a full overhead crane system isn’t the right fit.

4) Rigging that increases safety, precision, and throughput

Overhead cranes are only as safe as the rigging that connects the hook to the load. If your operation lifts awkward or long loads, consider spreaders early: What Does a Spreader Bar Do?

High-impact rigging upgrades

- Standardize sling types: match sling material to the load (edge conditions, heat, abrasion, finish sensitivity) and reduce variation across shifts.

- Use the right connectors: correct shackle/hook selection improves load alignment and reduces side loading.

- Add a spreader beam when needed: reduces sling angle forces, improves stability, and protects the load and attachment points.

If you want fewer “problem lifts”:

Build a “go-to kit” for common picks (slings + shackles + hooks + a beam option). That’s one of the simplest ways to boost speed and reduce incidents.

5) Inspection, training, and compliance (the “keep operating” section)

Overhead crane programs succeed when training + inspection are treated as operational essentials—not paperwork.

Get lifting equipment inspected and documented to current industry expectations—especially important for bridge/overhead crane operations, below-the-hook devices, and rigging gear used daily.

Build operator and rigger awareness with training that helps teams lift safely, communicate clearly, and reduce avoidable downtime.

Recommended reading for your program

Buyer’s checklist (copy/paste into your quote request)

- Max load weight (include rigging + below-the-hook device weight): ________

- Typical load weight: ________

- Lift height (hook travel needed): ________

- Span / coverage area: ________

- Duty cycle (lifts per hour/day, % of max load): ________

- Environment (indoor/outdoor, corrosion, heat, washdown): ________

- Hoist preference (manual/electric/pneumatic; chain vs wire rope): ________

- Load type (long, flexible, delicate, off-center): ________

- Rigging needed (slings, shackles, hooks, spreader beam): ________

- Inspection/training needs: ________

Next steps

Use the links below to build your package, then request a quote with your checklist details.

Content suitability + improvements (so it performs for your buyers)

If your audience expects a deep engineering discussion of runway/structural calculations, that content typically requires project-specific drawings and isn’t a great fit for a general eCommerce blog post. Solution: keep this buyer’s guide focused on selection decisions buyers can make online (hoist, trolley, rigging, spreader beams, inspection/training), and add a short “Request a Quote” prompt asking for span, lift height, duty cycle, and environment. That approach aligns with what lifting.com sells well and converts higher-intent visitors.

Note: Always follow manufacturer instructions and applicable standards for lifting operations. When in doubt, consult a qualified professional.

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

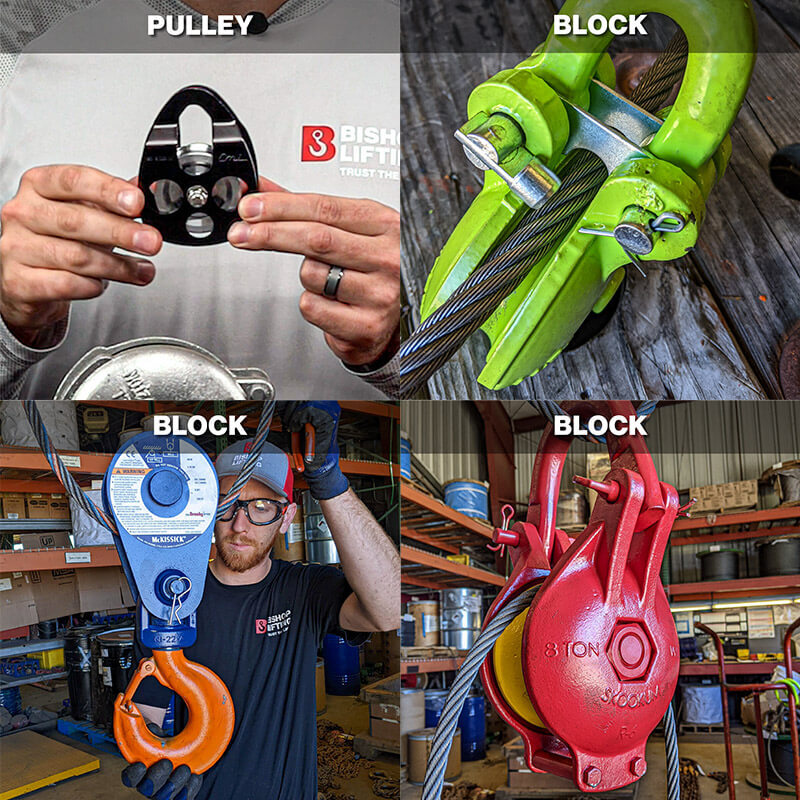

A Buyer’s Guide to Blocks & Snatch Blocks

If you’re lifting or pulling serious weight, you’re usua…

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

Rigging + Below-the-Hook Devices

A spreader bar (often called a spreader beam in product catalogs)…

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

A practical, standards-minded guide for selecting and rigging a snatch block to redirect a line, i…

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

(What Changed + What to Do Next)

There isn’t one single “new OSHA fall protection standard” that r…

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

Rigging Hardware Guide

Shackles are load-rated connectors used to join slings, chain, wire rope,…

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Synthetic winch lines (often HMPE/UHMWPE) deliver high strength with less weight—when they’re ins…

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026

In day-to-day lifting and rigging, the most commonly used shackle is typically the screw pin ancho…

What Are the Four Basic Types of Turnbuckle End Fittings?

Dec 30th 2025

Turnbuckles • End Fittings • Rigging Connections

Turnbuckle end fittings determine how your tensi…

What Is a Turnbuckle Used for in Rigging?

Dec 23rd 2025

Rigging Hardware Education • Tensioning • Best Practices

A turnbuckle is a precision tensioning c…