The Complete Buyer’s Guide to Overhead Cranes

Feb 13th 2026

A practical, standards-minded guide for selecting an overhead crane system—and the hoist + rigging gear that makes it safe, efficient, and compliant.

Quick reality check (so this guide matches your audience):

Many teams use “overhead crane” to mean the complete bridge crane system (runway, bridge, trolley, controls) plus the items you buy most often—hoists, trolleys, slings, shackles, hooks, and below-the-hook devices. Lifting.com is especially strong on the equipment…

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

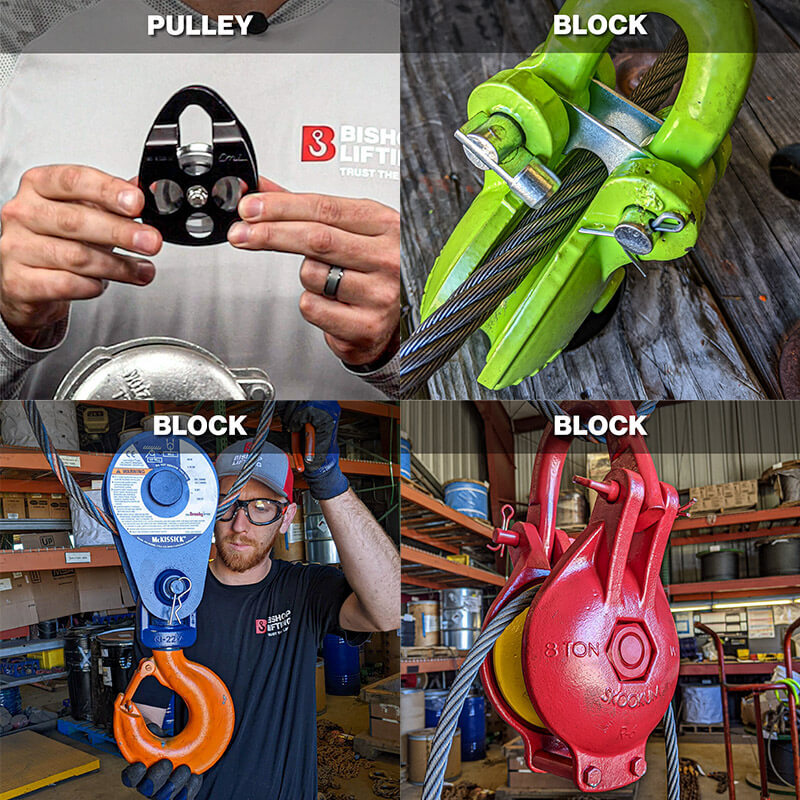

A Buyer’s Guide to Blocks & Snatch Blocks

If you’re lifting or pulling serious weight, you’re usually not looking for a light-duty “pulley.” You’re looking for a rigging block or a snatch block—built for industrial loads, wire rope, and real jobsite conditions.

In this guide you’ll learn:

What “heavy-duty pulley” really means in rigging terms (blocks vs. pulleys)

How to choose the right block/snatch block for your load and line…

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

Rigging + Below-the-Hook Devices

A spreader bar (often called a spreader beam in product catalogs) is used when you need to control sling angles, protect the load, and stabilize a lift—especially on long, flexible, or multi-pick loads.

Shop Spreader Bars + Beams Read: What Does a Spreader Bar Do?

Quick Decision: Use a Spreader Bar When…

You need wider sling separation to reduce sling loading from tight angles.

The load is long, flexible, or prone to bending (pipe, panels,…

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

A practical, standards-minded guide for selecting and rigging a snatch block to redirect a line, increase pulling efficiency, and reduce strain on your equipment—without guesswork.

Quick answer

Inspect the block and rigging, confirm load/line ratings, choose the correct connection point, open the side plate, seat the rope/wire rope fully in the sheave groove, close and secure the pin/side plate, then tension the system slowly while watching for side-loading, misalignment, and snag point…

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

(What Changed + What to Do Next)

There isn’t one single “new OSHA fall protection standard” that replaces everything—most requirements have existed for years. What’s changed recently is how OSHA has clarified and updated specific requirements (notably fixed ladder safety and PPE fit in construction) and how employers should plan, equip, and document compliance.

Fast clarity

There isn’t a single “new” fall protection rule replacing the old ones.…