What are the three types of slings?

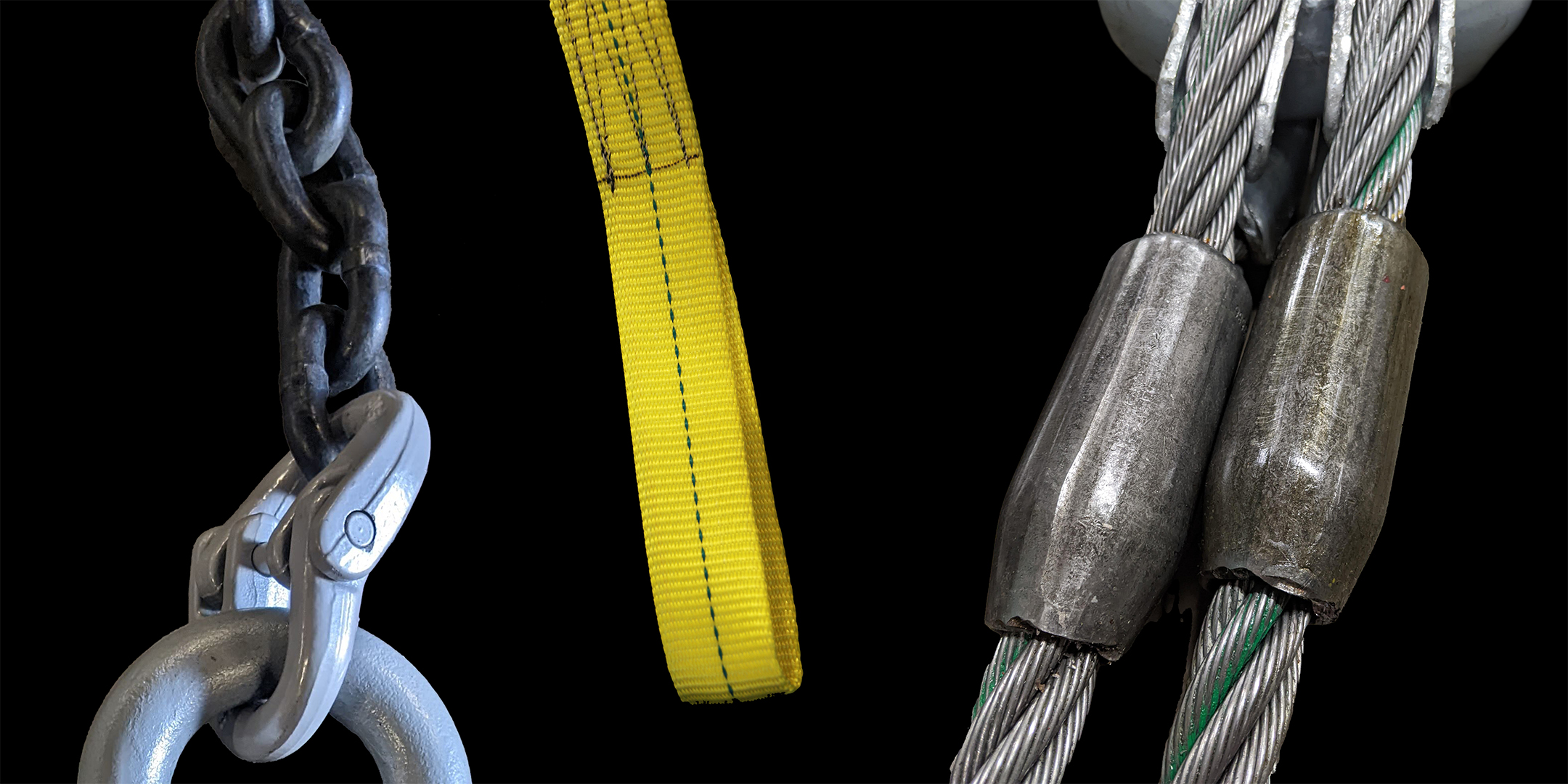

In lifting and rigging, knowing the types of slings is key for safety and efficiency. There are three main types: synthetic, wire rope, and chain slings. Each has its own construction, capacity, and best uses.

Synthetic slings are versatile and light. Made from nylon, polyester, and polypropylene, they're great for handling delicate surfaces. They come in different colors to show their lifting capacity, making things safer.

Wire rope slings are strong and long-lasting. They're made from steel cables and are perfect for heavy lifting. They can handle tough conditions like rough surfaces and high heat. You can get them in single-leg or multi-leg styles for different needs.

Chain slings are the go-to for lifting very heavy loads. They're made of steel links and last a long time. You can choose from single-leg or double-leg styles to fit different load shapes.

Key Takeaways

- Three main types of slings are used in lifting and rigging: synthetic, wire rope, and chain slings.

- Synthetic slings provide lightweight flexibility, ideal for delicate surfaces and varying load sizes.

- Wire rope slings are preferred for their strength, durability, and ability to handle heavy lifting in harsh environments.

- Chain slings are suitable for the heaviest loads, known for their robustness and longevity.

- Each type's suitability depends on factors like load weight, environmental conditions, and safety requirements.

Synthetic Slings: Versatile and Lightweight

Synthetic slings are made from strong materials like nylon and polyester. They are known for being versatile and lightweight. These slings are great for many lifting tasks. They come in different types, such as web slings and round slings.

Materials and Varieties

Synthetic lifting slings are often made from nylon and polyester. You can choose from flat webbing slings, round slings, and endless slings. Each type has its own benefits. For example, nylon is good at absorbing shocks, while polyester helps control loads better.

Advantages and Applications

These slings have many advantages. They are light, affordable, and don't rust, making them perfect for lifting in warehouses. The color-coded system makes it easy to see the sling's capacity. While they're not for heavy loads or high heat, they're great for many tasks because they protect loads well.

Safety Considerations

Keeping synthetic slings safe is key to their long life and good performance. It's important to check them for damage, store them right, and use them as the maker says. Also, keep them away from chemicals and sharp things to keep them safe and working well. Following these steps helps keep web slings and round slings in good shape for safe lifting.

Wire Rope Slings: Strength and Durability

Wire rope slings are made from braided steel wires. They are known for their great strength and cost-effectiveness. In industries like construction, where lifting heavy loads is common, they are a must-have.

These slings can handle abrasions, fatigue, and temperatures up to 400 degrees Fahrenheit. This makes them a reliable choice for tough environments.

Even though they are heavy and stiff, wire rope slings are very durable. They stand up well to harsh conditions and last a long time. This makes them a top choice when you need strong and cost-effective rigging equipment.

To keep wire rope slings safe and effective, it's important to check them regularly for kinks, cuts, and wear. Keeping them in good shape ensures they can safely lift heavy loads. This helps increase the durability of rigging equipment in lifting operations.

Conclusion

Looking at synthetic, wire rope, and chain slings shows each has its own benefits for different needs. Choosing the right sling is key for safe and efficient work. It's important for lifting and rigging tasks. Also, taking into consideration OSHA guidelines for slings.

Synthetic slings are great for lighter loads and delicate items. They're easy to handle and protect the load from damage. On the other hand, wire rope slings are strong and last long. They're a good choice for tough jobs where they can resist wear and tear.

Chain slings are top-notch for heavy-duty tasks. They're built tough to handle big loads safely. When picking a sling, think about the load size, the work environment, and how you'll be handling it.

It's crucial to keep slings in good shape, follow safety rules, and use them right. Knowing about the different slings and their uses helps industries lift safely and efficiently. This keeps workers safe and boosts work output.

If you are in need of in stock ready to ship slings you can buy online and slings for sale online visit our online store at Bishop Lifting for all your rigging equipment and supply needs including all types of slings.

FAQ

What are the three types of slings?

There are three main types of slings: synthetic, wire rope, and chain slings. Each type is suited for different loads and conditions. They meet various safety standards.

What materials are synthetic slings made of?

Synthetic slings are made from nylon, polyester, or polypropylene. These materials are light, flexible, and great for lifting.

What are the advantages of synthetic slings?

Synthetic slings are light and flexible. They are also cost-effective and have a color-coded system for easy capacity identification. They don't rust and protect the load, making them perfect for general lifting in warehouses.

How do wire rope slings differ from synthetic slings?

Wire rope slings use alloy steel cables for strength and durability. They're great for heavy lifting and tough conditions. Synthetic slings are better for lighter loads and delicate surfaces.

What are the typical applications of wire rope slings?

Wire rope slings are used in tough industries like construction. They handle heavy loads and can take rough conditions, heat, and abrasion up to 400 degrees Fahrenheit.

Why are chain slings preferred for industrial applications involving heavy lifting?

Chain slings are made from strong alloy steel. They can bear heavy loads and resist high temperatures and tough environments. They're perfect for heavy industrial tasks, like in steel mills and foundries.

What configurations are available for chain slings?

Chain slings come in single-leg and multi-leg types. These options help fit different load shapes and sizes. They make handling loads easier in various industries.

How does the color-coded system of synthetic slings enhance safety?

The color-coded system on synthetic slings shows the load capacity quickly. This reduces the chance of overloading and makes lifting safer.

How crucial is regular inspection for wire rope slings?

Checking wire rope slings often for kinks, wear, and damage is key. It keeps them safe and working right. This helps avoid accidents and makes the slings last longer.

What innovations are seen in chain slings for heavy-duty lifting?

New innovations like Kito's Grade 100 chains are stronger and lighter than old Grade 80 chains. These updates show why chain slings are top choices for heavy lifting.

Lifting vs. Rigging Equipment: What’s the Difference (and What You Actually Need)?

Feb 24th 2026

The Complete Buyer’s Guide to Overhead Cranes

Feb 13th 2026

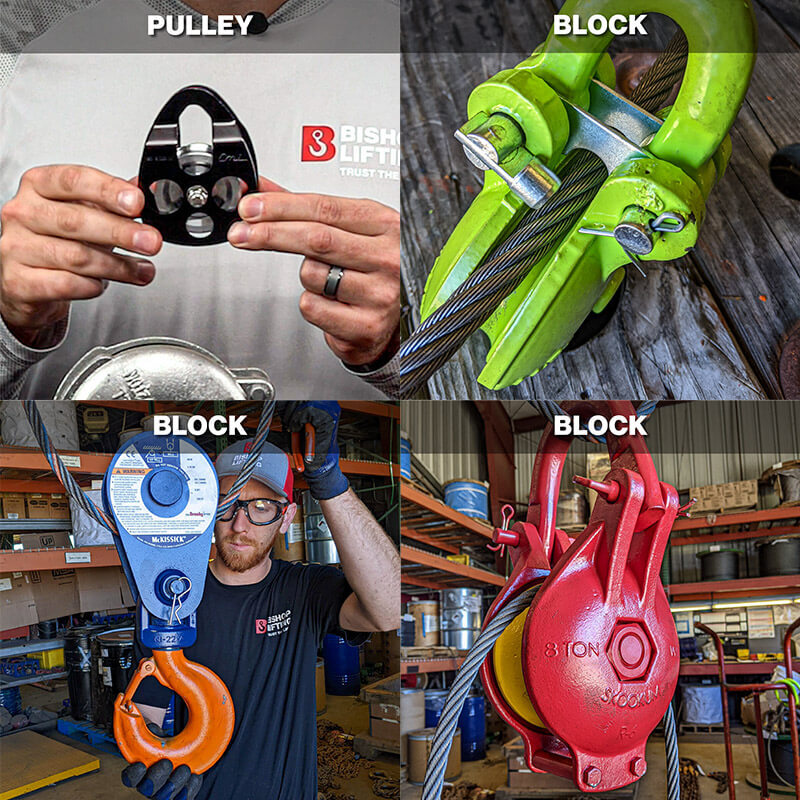

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026