What Are the Four Types of Rigging?

Rigging is an essential process across industries such as construction, entertainment, and manufacturing. Knowing the different types of rigging systems is crucial for ensuring safety, efficiency, and project success. This guide explores the four main types of rigging: rope rigging, wire rope rigging, synthetic rigging, and chain rigging.

Each type of rigging plays a distinct role and is designed for specific applications. Understanding their features, advantages, and limitations allows professionals to choose the best option for their projects, reducing risks, improving productivity, and saving costs.

What Is Rigging?

Rigging involves using specialized equipment and techniques to lift, move, and position heavy loads safely and efficiently. It is integral to industries like construction, manufacturing, and logistics, as well as in creative fields like theater and film production.

Basic Components of Rigging

Successful rigging requires a combination of proper rigging equipment, supplies and trained personnel. Key components include:

- Ropes and chains

- Wire ropes and synthetic slings

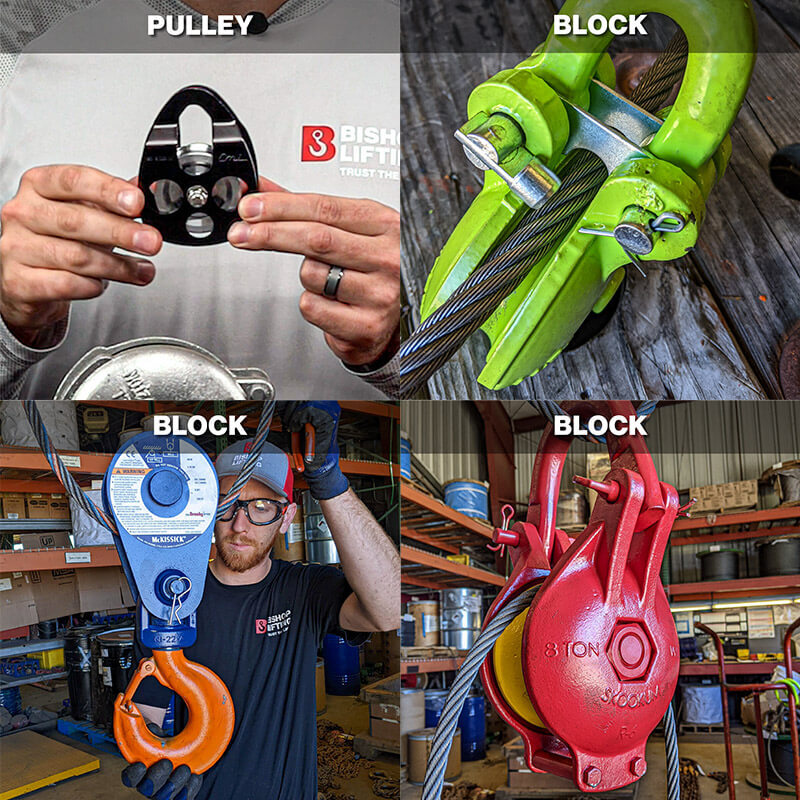

- Pulleys and winches

- Hoists and cranes

- Load calculators and safety equipment

These components work together to ensure heavy loads are moved securely, minimizing risks and ensuring project efficiency.

The Four Types of Rigging

1. Rope Rigging

Rope rigging has been used for centuries due to its versatility and simplicity. Made from natural or synthetic fibers, it is commonly used in applications like sailing, rock climbing, and light-duty lifting.

Key Features:

- Lightweight and flexible

- Affordable and easy to handle

- Suitable for non-corrosive environments

Applications:

- Outdoor recreational activities

- Temporary load handling in construction and event setups

2. Wire Rope Rigging

Wire rope rigging is a durable and high-strength option, ideal for demanding tasks. It consists of multiple strands of steel wire twisted into a helical structure.

Key Features:

- Exceptional strength and durability

- Resistance to abrasion and wear

- Suitable for heavy-duty industrial applications

Applications:

- Construction site operations

- Marine and offshore industries

- Heavy machinery transportation

3. Synthetic Rigging

Synthetic rigging is made from materials like nylon, polyester, or high-performance fibers. It is lightweight, flexible, and resistant to environmental damage, making it a favorite for specialized applications.

Key Features:

- Corrosion-resistant and easy to handle

- High strength-to-weight ratio

- Non-conductive properties

Applications:

- Entertainment industry for stage setups

- Aviation and aerospace

- Sports and recreational activities

4. Chain Rigging

Chain rigging is known for its robustness and reliability in handling heavy loads. It is typically made from high-grade steel, ensuring durability and long-term use in rugged conditions.

Key Features:

- Excellent tensile strength

- Resistance to high temperatures and harsh conditions

- Adjustable and reusable

Applications:

- Industrial lifting and hoisting

- Rigging in extreme temperature environments

- Heavy equipment anchoring

Safety Principles in Rigging Operations

Rigging operations demand strict adherence to safety standards to prevent accidents. Key safety principles include regular inspection and maintenance of equipment, proper training and certification for personnel, use of personal protective equipment (PPE), and development of detailed safety and emergency response plans. Following these guidelines ensures a secure work environment and minimizes risks during rigging operations.

How to Choose the Right Rigging Type

Selecting the best rigging system depends on the specific requirements of your project. Consider the load capacity, environment, durability, and cost. Consulting rigging experts and understanding the pros and cons of each type will help ensure the right choice for your needs.

Conclusion

Rigging plays a pivotal role in the safe and efficient handling of heavy loads across industries. The four main types—rope rigging, wire rope rigging, synthetic rigging, and chain rigging—offer unique benefits tailored to specific applications. By understanding their characteristics and adhering to safety best practices, you can optimize your operations and achieve project success.

At Bishop Lifting we provide all the rigging supplies and equipment that you need. We have rigging supplies and equipment in stock and ready to ship directly to you at the best prices.

FAQs

What are the four types of rigging?

The four main types are rope rigging, wire rope rigging, synthetic rigging, and chain rigging.

What makes chain rigging unique?

Chain rigging offers exceptional tensile strength and is ideal for rugged, high-temperature environments.

Why is synthetic rigging a popular choice?

Synthetic rigging is lightweight, corrosion-resistant, and versatile, making it suitable for specialized and delicate tasks.

What safety measures are essential for rigging?

Key safety measures include regular equipment inspections, proper training, and the use of PPE.

How do I decide which rigging type to use?

Evaluate your project's load requirements, environment, and budget, and consult with rigging professionals for tailored advice.

By leveraging this guide, you can ensure your rigging operations are both safe and effective while meeting your project’s specific demands.

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026

What Are the Four Basic Types of Turnbuckle End Fittings?

Dec 30th 2025

What Is a Turnbuckle Used for in Rigging?

Dec 23rd 2025