Product Description

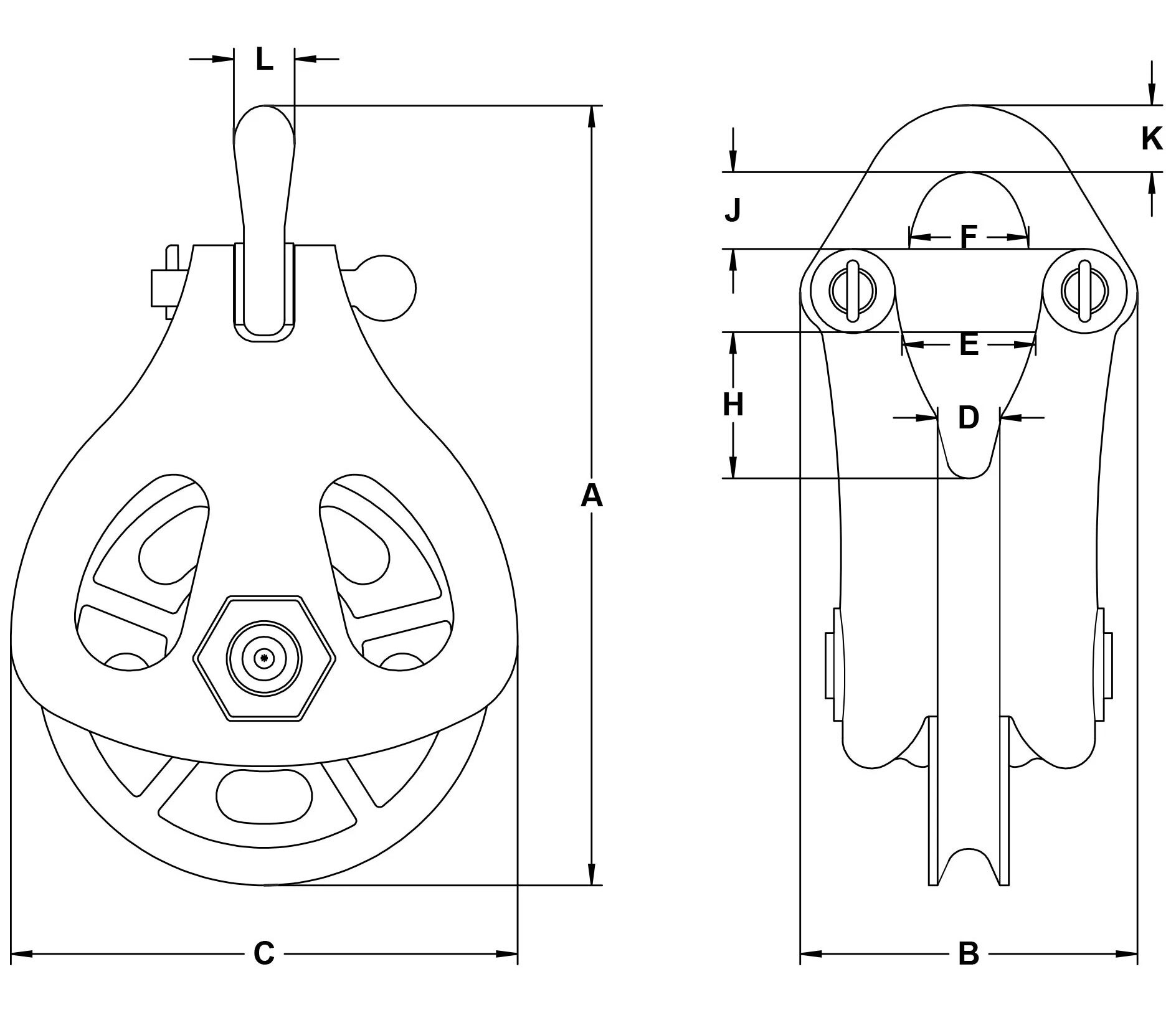

Ropemaster 515A Half-Sided Block – 15" Alloy Sheave

The Ropemaster 515A Half-Sided Block is built for larger rigging applications where strength and reliability are critical. Outfitted with a 15" alloy steel sheave and Timken tapered roller bearings, it ensures long service life and smooth performance under load. Designed for 7/8" to 1" wire rope with a 15-ton working load limit, the 515A combines heavy-duty durability with the weight-saving benefits of a half-sided frame.

Key Features:

- 15" alloy sheave with Timken tapered roller bearings

- Half-sided design reduces block weight while maintaining rugged strength

- Recessed sheave prevents binding and protects wire rope

- Quick-access draw pin for fast reeving and attachment swaps

- Cast alloy steel side plates for long-term durability

- Meets ASME B30.26-1 standards

Specifications:

| Sheave Diameter | 15" |

|---|---|

| Wire Rope Range | 7/8" – 1" |

| Working Load Limit | 15 Tons |

| Weight | 73 lbs |

| A (Height) | 24.25" |

| B (Thickness) | 6" |

| C (Width) | 15.5" |

| D (Throat Bottom) | 2.38" |

| E (Inside Throat Width) | 3" |

| F (Yoke Width Above) | 3" |

| G (Throat Height) | 7.63" |

| H (Throat Height Below) | 3.25" |

| J (Throat Height Above) | 2.25" |

| K (Yoke Bar Height) | 1.5" |

| L (Yoke Bar Width) | 1.63" |

Specifications

Safety Notice

Although Bishop Lifting strives to manufacture and sell the highest quality rigging and safety gear, use of the gear is dangerous if not used correctly by competent trained professionals. Bishop Lifting disclaims any liability resulting from the misuse of its rigging and safety gear. Please take a moment to more thoroughly review our disclaimer.

Bishop Lifting rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Bishop Lifting disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Bishop Lifting should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.