What Are the Four Basic Types of Turnbuckle End Fittings?

Dec 30th 2025

Turnbuckles • End Fittings • Rigging Connections

Turnbuckle end fittings determine how your tensioning system connects to anchor points, shackles, eye bolts, and other rigging hardware. The right end fitting improves alignment, reduces unintended loading, and helps keep your assembly stable over time. Below are the four most common end-fitting types you’ll encounter in professional rigging and industrial tensioning.

Safety First: End Fittings Affect Risk

Choose end fittings based on connection method, in-line loading, and the need for positive retention. Avoid side-loading, confirm thread engagement, and never exceed the Working Load Limit (WLL). If the application involves overhead lifting, only use hardware that is specifically rated and approved for that use by the manufacturer and your lift plan.

Jump to a fitting type:

Why End Fittings Matter in Rigging

Connection Compatibility

End fittings determine what you can connect to (shackles, eye bolts, pad eyes, pinned clevis points, etc.).

Load Path Control

The right fitting helps keep the assembly in-line and reduces the chance of binding or unintended loading.

Retention & Risk

Jaw ends offer pin retention. Hooks are fastest to attach but can be easier to unintentionally unseat in the wrong setup.

Quick translation (how Lifting.com categories map to real-world use):

Most professional setups are built around Jaw & Jaw, Jaw & Eye, and Eye & Eye turnbuckles. Stub/stud ends are specialized. Hook ends are commonly found in light-duty utility tensioning and should be chosen carefully based on application.

Shop Category

Turnbuckles

Browse turnbuckles by end fitting and application—ideal when you need adjustable tensioning for wire rope, cable, or structural assemblies. Filter by configuration to match your connection points and reduce setup time.

Shop Turnbuckles

Jaw/Jaw • Jaw/Eye • Eye/Eye • Specialty options

1) Eye End Fittings

Eye ends provide a closed attachment point that commonly pairs with shackles, links, and other connectors. They’re often selected for assemblies where you want straightforward compatibility and an in-line pull.

Best for

Shackle connections, pad eyes, link-style connectors, and setups that benefit from a closed attachment point.

Watch out for

Misfit hardware that introduces angles or binding. Keep the system aligned and avoid side-loading.

Category Intro

Eye & Eye Turnbuckles

If both connection points are loop-style, Eye & Eye turnbuckles keep selection simple. They’re a strong fit when you’re building a tensioning assembly around shackles or link-type connectors.

Shop Eye & Eye Turnbuckles 2) Jaw (Clevis) End Fittings

Jaw ends are clevis-style fittings secured with a pin/bolt. They’re commonly chosen when you want positive retention and a more secure, semi-permanent connection compared to open-ended hardware.

Best for

Pinned connection points, clevis brackets, and assemblies where you don’t want connections to “walk out” during vibration or movement.

Watch out for

Incorrect pin sizing or missing retention. Confirm pin fit, cotter/retainer use, and keep the load path in-line.

Category Intro

Jaw & Jaw Turnbuckles

When both ends need pinned retention, Jaw & Jaw is a go-to choice. It’s often preferred for semi-permanent rigging and structural tensioning where secure attachment matters.

Shop Jaw & Jaw Turnbuckles Category Intro

Jaw & Eye Turnbuckles

Need a pinned connection on one side and a loop-style connection on the other? Jaw & Eye is the practical hybrid—popular for mixed connection points without redesigning the assembly.

Shop Jaw & Eye Turnbuckles 3) Hook End Fittings

Hook ends are designed for fast attachment and removal. They’re common in light-duty utility tensioning, temporary setups, and situations where speed matters. In professional rigging, hooks require extra attention because open connections can be easier to unintentionally unseat if the system shifts.

Important note on hook-style “midget” turnbuckles

Many hook-style utility turnbuckles are intended for static, non-critical loads (examples include fencing, banners, and light tensioning). Always verify the product’s rating and intended use before selecting it for any rigging plan.

Best for

Quick connect/disconnect and light utility tensioning where the system is stable and the application is appropriate for the hardware rating.

Watch out for

Unintended disengagement and off-axis loading. If the connection could move, a pinned or closed connection is often the safer choice.

Browse Turnbuckles

Looking for the right configuration? Start with the full Turnbuckles category and narrow by end fitting type and application.

View All Turnbuckles 4) Stub / Stud End Fittings (Specialty)

Stub (or stud) ends are a specialty style used when you need a threaded end designed for specific integration—often in applications where components are built into a structure or used to apply controlled separation/positioning forces. This style is less “universal” than eye/jaw/hook and is typically selected for purpose-built assemblies.

Best for

Specialty applications where a threaded “stub” end integrates into a system design (often more engineered than general field rigging).

Watch out for

Misapplication. Confirm intended use, load rating, and how the stub end interfaces with the rest of the assembly.

Category Intro

Stub End Turnbuckles

Stub end turnbuckles are a strong option when your application calls for a specialty threaded end style. If your system is engineered around stub/stud connections, this category helps you spec the right configuration faster.

Shop Stub End Turnbuckles What About “Combination” End Fittings?

In real-world rigging, “combination” typically means mixing end styles to match your anchor points—most commonly Jaw & Eye. The right combination is the one that keeps the system compatible, aligned, and retained under expected conditions.

Companion Category

Shackles

Shackles are one of the most common connectors used with eye-style fittings and many mixed assemblies. Choosing the right shackle style and pin type improves connection fit, alignment, and serviceability.

Shop Shackles

Browse screw pin and bolt-type options

Selection Checklist (Field-Friendly)

- Match the connection: jaw for pinned points, eye for closed/loop connections, hooks for fast utility setups, stub for specialty integration.

- Keep pulls in-line: turnbuckles are designed for straight-line tensioning—avoid angles that create side-load.

- Confirm WLL and markings: the turnbuckle is only one part of the system—every component must be rated appropriately.

- Maintain thread engagement: don’t back an end fitting out too far; keep adequate engagement for stability and strength.

- Inspect before use: remove from service for bent parts, damaged threads, cracks, heavy corrosion, or deformation.

Related Lifting.com Guides

Keep building your rigging knowledge with these field-friendly resources:

Ready to choose the right end fitting?

Shop by configuration to match your connection points and build a cleaner, safer tensioning system.

Reminder: Always follow manufacturer guidance, site procedures, and your lift plan. Inspect rigging hardware before use and remove damaged components from service.

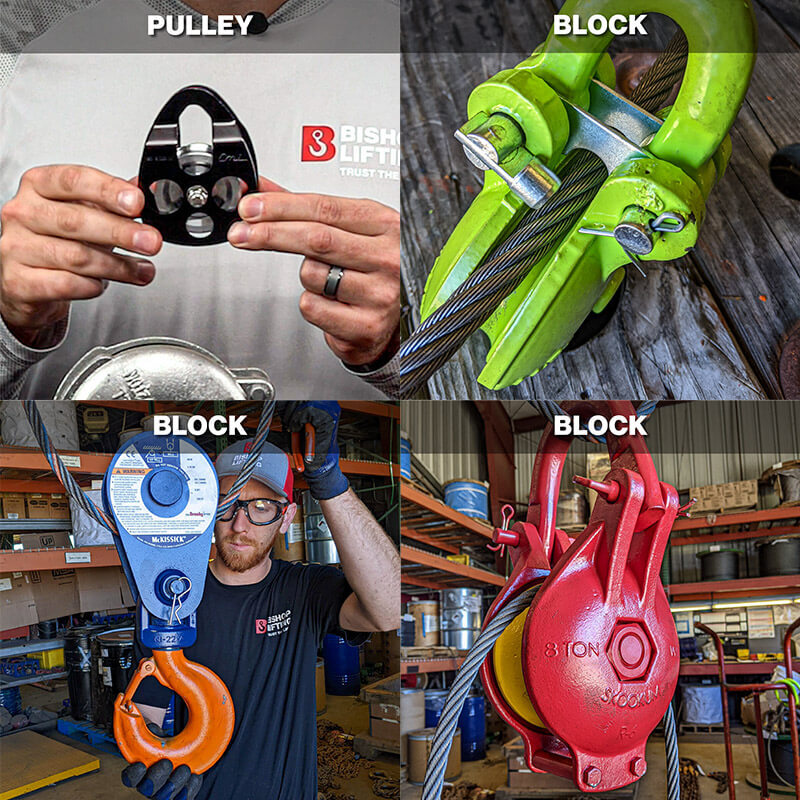

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

A Buyer’s Guide to Blocks & Snatch Blocks

If you’re lifting or pulling serious weight, you’re usua…

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

Rigging + Below-the-Hook Devices

A spreader bar (often called a spreader beam in product catalogs)…

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

A practical, standards-minded guide for selecting and rigging a snatch block to redirect a line, i…

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

(What Changed + What to Do Next)

There isn’t one single “new OSHA fall protection standard” that r…

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

Rigging Hardware Guide

Shackles are load-rated connectors used to join slings, chain, wire rope,…

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Synthetic winch lines (often HMPE/UHMWPE) deliver high strength with less weight—when they’re ins…

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026

In day-to-day lifting and rigging, the most commonly used shackle is typically the screw pin ancho…

What Are the Four Basic Types of Turnbuckle End Fittings?

Dec 30th 2025

Turnbuckles • End Fittings • Rigging Connections

Turnbuckle end fittings determine how your tensi…

What Is a Turnbuckle Used for in Rigging?

Dec 23rd 2025

Rigging Hardware Education • Tensioning • Best Practices

A turnbuckle is a precision tensioning c…