Product Description

Gunnebo M & MF Master Links (Grade 100)

Gunnebo M and MF Master Links are heavy-duty, welded alloy steel links designed for use with Grade 100 chain slings and other lifting assemblies. The M series features a consistent round profile, while the MF series incorporates an engineered flat to accept certain compatible fittings (such as components from the GrabiQ lineup or Crosby S-1325 Omega Links). This versatility makes them a reliable choice for both standard chain sling assemblies and specialized rigging applications.

Key Features:

- Manufactured from quenched & tempered, fine grain alloy steel sourced from European mills.

- Individually proof-tested and certified to values shown in specifications.

- Meets or exceeds requirements of EN 1677-4, ASTM A952/A952M, AS 3775.2, and AS 3776:2015.

- Fatigue rated to at least 20,000 cycles at 1.5x WLL.

- 5:1 design factor (required for chain, wire, or synthetic rope applications).

- Traceable through unique Product Identification Codes (PIC), marking includes: grade, chain size, “SWE,” “Gunnebo,” and BG/DGUV ID (H32).

- Compatible with chain, wire rope, and synthetic rope assemblies.

Identification & Markings:

- M: Single-type master link (round profile).

- MF: Single-type master link with engineered flat.

- Other variants include MT (master link assembly), MFH (engineered flat for DIN style crane hooks), and MFX (enlarged with engineered flat).

- Markings include Gunnebo brand, country of origin (Sweden), and full traceability code.

Specifications:

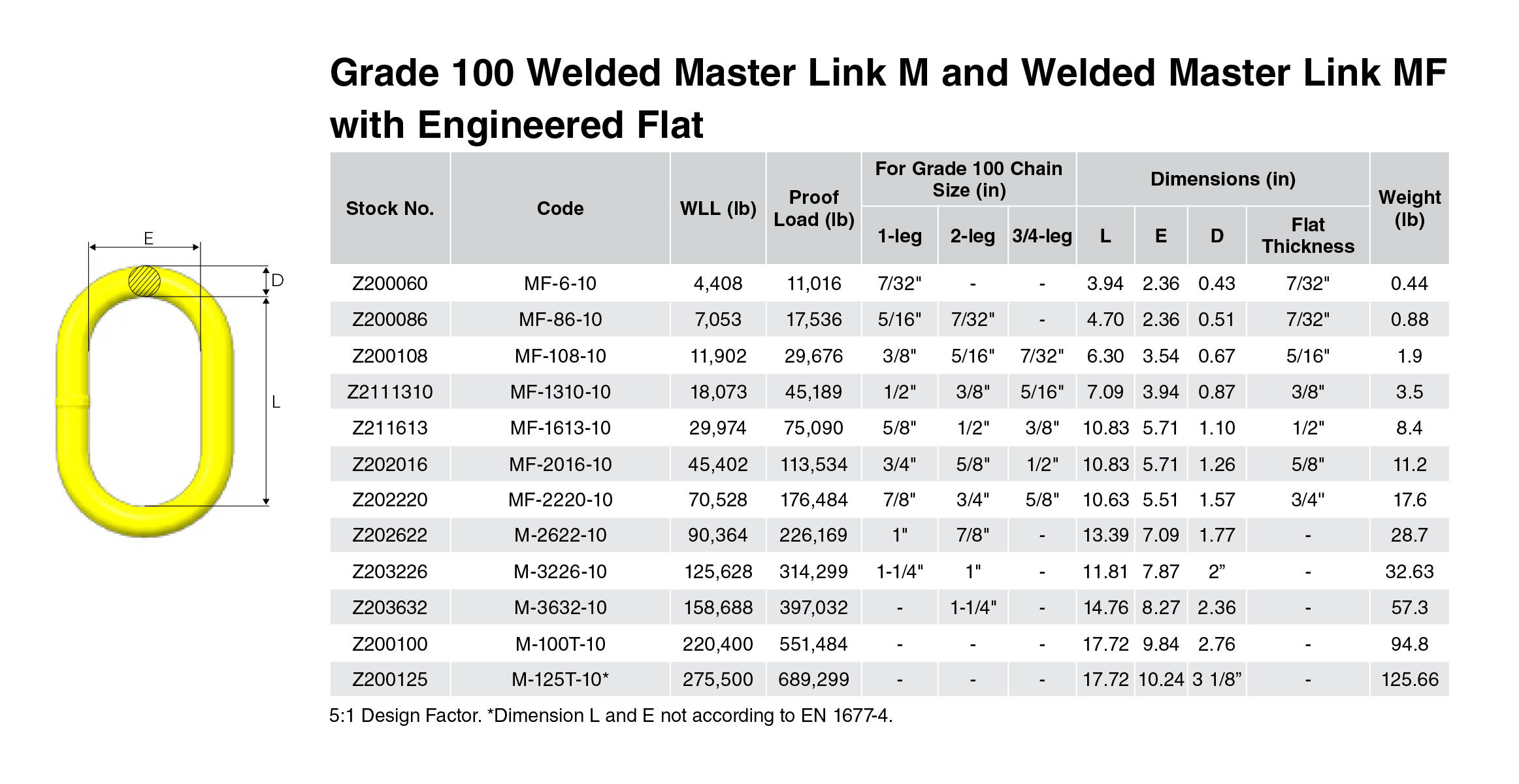

- Working Load Limits (WLL) range from 4,408 lbs to 275,500 lbs depending on size.

- Proof loads from 11,016 lbs up to 689,299 lbs.

- Available in sizes from 7/32" chain up to 1-1/4" chain, with larger capacities available in heavy-duty M models.

- Engineered flat thickness designed for secure seating with compatible couplers and links.

Whether you choose the M series for traditional round links or the MF series with engineered flats for enhanced compatibility, Gunnebo master links deliver strength, consistency, and long service life in demanding lifting operations.

Specifications

Safety Notice

Although Bishop Lifting strives to manufacture and sell the highest quality rigging and safety gear, use of the gear is dangerous if not used correctly by competent trained professionals. Bishop Lifting disclaims any liability resulting from the misuse of its rigging and safety gear. Please take a moment to more thoroughly review our disclaimer.

Bishop Lifting rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Bishop Lifting disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Bishop Lifting should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.