Product Description

Crosby G-2140 Alloy Bolt Type Anchor Shackles

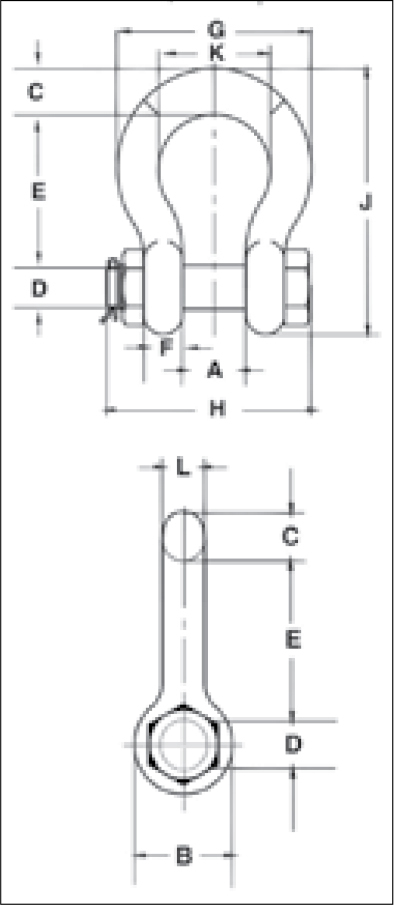

Crosby G-2140 Shackles are heavy-duty anchor shackles engineered for lifting and rigging in demanding environments. They feature quenched-and-tempered forged alloy steel bows and alloy bolts, permanent WLL markings, and compliance with major industry standards. The dimensional drawing is provided for quick reference.

Features

- Forged Alloy Steel Construction: Alloy bows and alloy bolts, quenched & tempered for superior strength.

- Grade 8 Performance: Meets or exceeds the performance requirements of Grade 8 shackles.

- Permanent Identification: Working Load Limit (WLL) is permanently shown on every shackle.

- Material Range: Forged alloy steel from 2 through 250 metric tons; 400 metric ton model is cast alloy steel.

- Finish Options:

- 30, 40, 55, and 85 metric ton shackles – bows available galvanized (G) or self-colored (S); bolts galvanized and painted red.

- Size 3/8" is mechanically galvanized.

- 120, 150, and 175 metric ton shackles – hot-dip galvanized bows; bolts Dimetcoted and painted red.

- 200, 250, 300, and 400 metric ton shackles – Dimetcoted bows; bolts Dimetcoted and painted red.

- Temperature Rating: Approved for use from -40°F (-40°C) to 400°F (204°C).

- Impact Rated: Shackles can meet DNV impact requirements of 42 Joules (31 ft-lb) at -4°F (-20°C).

- Crosby COLD TUFF® Option: Available models meet DNV rules for lifting applications requiring enhanced toughness.

- Large Size Traceability: Shackles 200 metric tons and larger are furnished with serialized bolts and bows, material certification, and magnetic particle inspection. Certification must be requested at time of order.

- Certifications: Type Approval available per ABS 2016 Steel Vessel Rules and ABS Guide for Certification of Lifting Appliances (certificates available upon request).

- Standards Compliance: Meets or exceeds all requirements of ASME B30.26 for identification, ductility, design factor, proof load, and temperature rating. G-2140 also meets Federal Specification RR-C-271H, Type IVA, Grade B, Class 3 (except contractor provisions).

- Design Factors: 4.5:1 (2–21t), 5.4:1 (30–175t), 4:1 (200–400t). Proof load = 2× WLL.

- Look for the Red Pin®: The mark of genuine Crosby quality and traceability.

Specifications

| Nominal Size (in) | WLL (t) | G-2140 Stock No. | Weight (lb) | A | B | C | D | E | F | G | H | J | K | L | M | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/8 | 2 | 1021015 | 0.33 | 0.66 | 0.91 | 0.38 | 0.44 | 1.44 | 0.38 | 1.78 | 2.17 | 2.49 | 1.03 | 0.38 | — | — |

| 7/16 | 2.67 | 1021020 | 0.49 | 0.75 | 1.06 | 0.44 | 0.50 | 1.69 | 0.41 | 2.03 | 2.51 | 2.91 | 1.16 | 0.44 | — | — |

| 1/2 | 3.33 | 1021029 | 0.79 | 0.81 | 1.19 | 0.50 | 0.64 | 1.88 | 0.46 | 2.31 | 2.80 | 3.28 | 1.31 | 0.50 | — | — |

| 5/8 | 5 | 1021038 | 1.68 | 1.06 | 1.50 | 0.69 | 0.77 | 2.38 | 0.58 | 2.94 | 3.56 | 4.19 | 1.69 | 0.63 | — | — |

| 3/4 | 7 | 1021047 | 2.72 | 1.25 | 1.81 | 0.81 | 0.89 | 2.81 | 0.69 | 3.50 | 4.15 | 4.97 | 2.00 | 0.75 | — | — |

| 7/8 | 9.5 | 1021056 | 3.95 | 1.44 | 2.09 | 0.97 | 1.02 | 3.31 | 0.81 | 4.03 | 4.82 | 5.83 | 2.28 | 0.88 | — | — |

| 1 | 12.5 | 1021065 | 5.66 | 1.69 | 2.38 | 1.06 | 1.15 | 3.75 | 0.92 | 4.69 | 5.39 | 6.56 | 2.69 | 1.00 | — | — |

| 1-1/8 | 15 | 1021074 | 8.27 | 1.81 | 2.69 | 1.25 | 1.25 | 4.25 | 1.04 | 5.16 | 5.90 | 7.47 | 2.91 | 1.13 | — | — |

| 1-1/4 | 18 | 1021083 | 11.7 | 2.03 | 3.00 | 1.38 | 1.40 | 4.69 | 1.16 | 5.75 | 6.69 | 8.25 | 3.25 | 1.29 | — | — |

| 1-3/8 | 21 | 1021092 | 15.8 | 2.25 | 3.31 | 1.50 | 1.53 | 5.25 | 1.28 | 6.38 | 7.21 | 9.16 | 3.63 | 1.42 | — | — |

| 1-1/2 | 30 | 1021110 | 18.8 | 2.38 | 3.62 | 1.62 | 1.63 | 5.75 | 1.39 | 6.88 | 7.73 | 10.00 | 3.88 | 1.53 | — | — |

| 1-3/4 | 40 | 1021138 | 33.8 | 2.88 | 4.19 | 2.25 | 2.00 | 7.00 | 1.75 | 8.81 | 9.33 | 12.34 | 5.00 | 1.84 | — | — |

| 2 | 55 | 1021156 | 49.9 | 3.25 | 4.81 | 2.40 | 2.25 | 7.75 | 2.00 | 10.16 | 10.41 | 13.68 | 5.75 | 2.08 | — | — |

| 2-1/2 | 85 | 1021174 | 103 | 4.12 | 5.81 | 3.12 | 2.75 | 10.50 | 2.62 | 12.75 | 13.58 | 17.90 | 7.25 | 2.71 | — | — |

| 3 | 120 | 1021192 | 162 | 5.00 | 6.50 | 3.63 | 3.25 | 13.00 | 3.00 | 14.62 | 15.13 | 21.50 | 7.88 | 3.12 | — | — |

| 3-1/2 | 150 | 1021218 | 268 | 5.25 | 8.00 | 4.38 | 3.75 | 14.63 | 3.75 | 17.02 | 20.33 | 24.88 | 9.00 | 3.62 | 4.00 | 1.80 |

| 4 | 175 | 1021236 | 318 | 5.50 | 9.00 | 4.56 | 4.25 | 14.50 | 4.00 | 18.00 | 21.20 | 25.68 | 10.00 | 4.00 | 4.00 | 1.80 |

| 4-3/4 | 200 | 1021234 | 461 | 7.25 | 10.50 | 5.00 | 4.75 | 15.19 | 4.58 | 20.84 | 24.04 | 27.81 | 11.00 | 4.75 | 4.00 | 1.80 |

| 5 | 250 | 1021243 | 608 | 8.50 | 12.00 | 5.62 | 5.00 | 18.50 | 4.85 | 23.62 | 24.87 | 32.61 | 13.00 | 5.00 | 4.00 | 1.80 |

| 6 | 300 | 1021252 | 797 | 8.38 | 13.00 | 6.06 | 6.00 | 18.72 | 4.89 | 24.76 | 26.22 | 34.28 | 13.00 | 5.88 | 4.00 | 1.80 |

| 7* | 400 | 1021478 | 1289 | 8.25 | 14.00 | 7.25 | 7.00 | 22.50 | 6.50 | 26.00 | 29.66 | 40.25 | 13.00 | 6.00 | 4.00 | 1.80 |

Notes: * 7" size is cast alloy steel. Sizes 3½" through 7" are furnished with round head bolts with a handle.

Specifications

Safety Notice

Although Bishop Lifting strives to manufacture and sell the highest quality rigging and safety gear, use of the gear is dangerous if not used correctly by competent trained professionals. Bishop Lifting disclaims any liability resulting from the misuse of its rigging and safety gear. Please take a moment to more thoroughly review our disclaimer.

Bishop Lifting rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Bishop Lifting disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Bishop Lifting should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.