What’s the Hardest Chain to Cut?

When you’re securing high-value equipment, vehicles, or inventory, chain performance determines whether an asset stays protected. Among industrial-grade options, Pewag security chains are trusted for exceptional hardness, engineered link geometry, and reliable resistance to cutting tools.

Why Chain Strength Matters

A security chain is a primary barrier against theft. To resist bolt cutters, prying tools, and abrasion, a chain must combine high-grade alloy steel, controlled heat treatment, and link shapes that limit tool leverage. That’s where Pewag excels—delivering professional-grade protection for construction, transportation, logistics, utilities, and high-security personal use.

What Makes a Chain Cut-Resistant

- Material & Heat Treatment: Hardened alloy steel links with very high surface hardness—rated up to ~62 HRC on the Rockwell C scale.

- Link Geometry: Square-profile (tapered) links reduce grip points for cutter jaws, making it substantially harder to gain purchase and apply force.

- Consistency & Tolerances: Precision-made links maintain strength at the bends and welds, where commodity chains often fail.

Why Professionals Trust Pewag

Pewag’s security chains are engineered for demanding environments and chosen when downtime or loss is simply unacceptable. Made in Europe by a manufacturer with centuries of chainmaking heritage, the combination of high hardness, square links, and protective sleeving delivers dependable performance in real-world scenarios.

- High Hardness (up to ~62 HRC): Helps resist standard bolt cutters and deformation.

- Square Links: Minimize tool bite and leverage for a measurable security advantage.

- Electro-galvanized finish (EG): Corrosion-resistant surface for outdoor use.

- Protective Sleeves: Reduce abrasion on painted, plated, or finished surfaces.

- Industrial Focus: Ideal for jobsite equipment, trailers, gates, containers, generators, and more.

We are an authorized Pewag dealer—your purchase is authentic and supported.

Real-World Applications

Teams deploy Pewag chains to secure trailers, machinery, tool chests, containers, motorcycles, and outdoor assets. The chains are built to frustrate attacks from bolt cutters and hacksaws and to meaningfully delay grinder attempts—buying critical response time and increasing the chance a theft attempt is abandoned.

Choosing the Right Pewag Chain

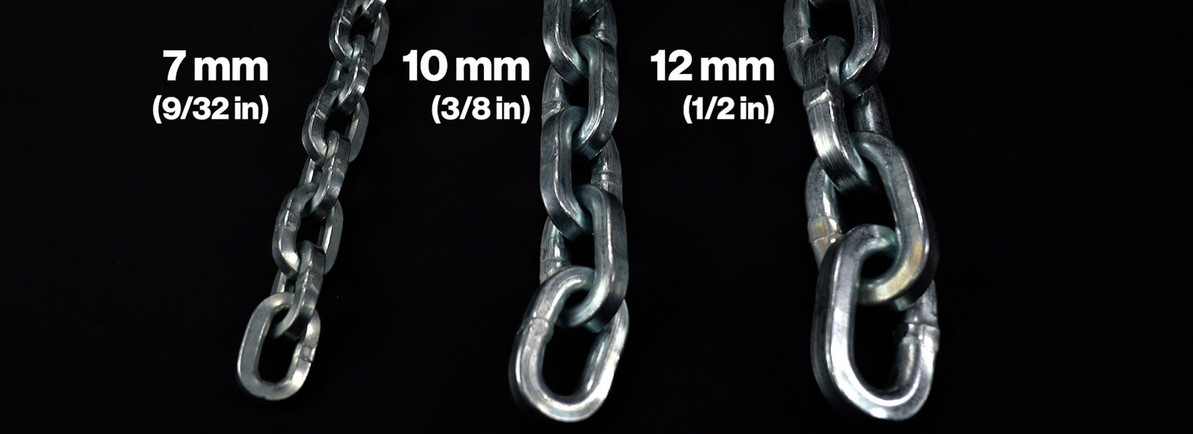

Match chain diameter and length to your threat level, lock compatibility, and anchor points. All models feature tapered square links and a corrosion-resistant EG finish.

| Chain Model | Link Type | Hardness / Depth | Compatible Padlock | Typical Use | Shop |

|---|---|---|---|---|---|

| Pewag 7 mm (9/32″) Security Chain | Tapered Square | 62 HRC @ 10% | Viro 4228 (Panzer Lock) | Motorcycles, bicycles, light equipment | Shop now |

| Pewag 10 mm (3/8″) Security Chain | Tapered Square | 62 HRC @ 10% | Viro 4126 (Panzer Lock) | Trailers, gates, generators, site equipment | Shop now |

| Pewag 12 mm (1/2″) Security Chain | Tapered Square | 62 HRC @ 6% | Viro 4153 (Monolith Lock) | Heavy machinery, high-risk locations | Shop now |

Pair your chain with a compatible high-security padlock (shrouded shackle recommended) sized for square links. Pewag chain bundles with Viro armored locks and sleeves are available.

FAQ

What makes Pewag chains harder to cut?

Hardened alloy steel treated to high Rockwell C surface hardness and square-profile links that reduce tool leverage and cutter bite.

Are Pewag chains weather-resistant?

Yes. The electro-galvanized finish and optional sleeves help resist corrosion and abrasion in outdoor environments.

Which chain diameter should I choose?

Choose 7 mm for portable setups and moderate threats; 10–12 mm for higher-risk environments, larger anchors, and longer dwell times.

Ready to Secure Your Assets?

Shop Pewag Security Chains on Lifting.com

Need help selecting the right diameter, kit, or lock pairing? Contact our team for recommendations based on your application.

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026

What Are the Four Basic Types of Turnbuckle End Fittings?

Dec 30th 2025

What Is a Turnbuckle Used for in Rigging?

Dec 23rd 2025

What’s the Best Material for Rigging?

Dec 18th 2025

What Is the 10-Foot Rule for Rigging?

Dec 15th 2025

What Are the Different Types of Climbing Ropes?

Dec 11th 2025

What Type of Rope Is Best for Climbing?

Dec 9th 2025

What Are the Two Types of Kernmantle Rope?

Nov 25th 2025