How to identify Crosby hooks?

It's important to know how to spot Crosby hooks for safe lifting. Crosby makes a variety, like the S-319, S-3316, S-320, and S-322 series. These are strong and dependable. You can tell they're Crosby hooks by certain features and markings. They have QUIC-CHECK® marks for quick checks. These marks help you quickly see if a hook has been misused or overloaded. Look for marks under the shank or eye and on the tip. If they don't line up, it might be damaged. Also, there are marks that show the correct angle for slings in the hook. You must follow Crosby's guidelines to keep hooks safe. They warn not to use damaged, bent, or worn hooks. Using real Crosby hooks is important. It ensures the load is held correctly and safely. This meets OSHA's rules.

Key Takeaways

- Recognizing distinct features and markings of Crosby hooks is vital for effective Crosby hook identification.

- Crosby hooks like the S-319, S-3316, S-320, and S-322 series are renowned for their durability.

- QUIC-CHECK® features include deformation and angle indicators for quick inspections.

- Deformation indicators are located just below the shank or eye and on the hook tip.

- Angle indicators denote the maximum included angle between two sling legs.

- Adhering to Crosby's application instructions and OSHA regulations ensures Crosby hook safety.

Understanding Crosby Hook Features and Markings

Crosby hooks are well-known for being strong and long-lasting. They have a history that goes back a hundred years in helping with rigging and lifting. Crosby puts each hook through a special heat treatment to ensure it is very strong. This care means lots of people trust these hooks for their work.

When checking a Crosby hook, workers look for special marks and features that help with safety. These hooks have marks that show if they've changed shape. This helps keep workers safe by spotting hooks that might not be safe to use.

Each type of Crosby hook has its own color, like platinum, gold, or red. This makes it easy for workers to tell which hooks are best for different jobs. It's a simple and fast way to know if a hook is right for the task.

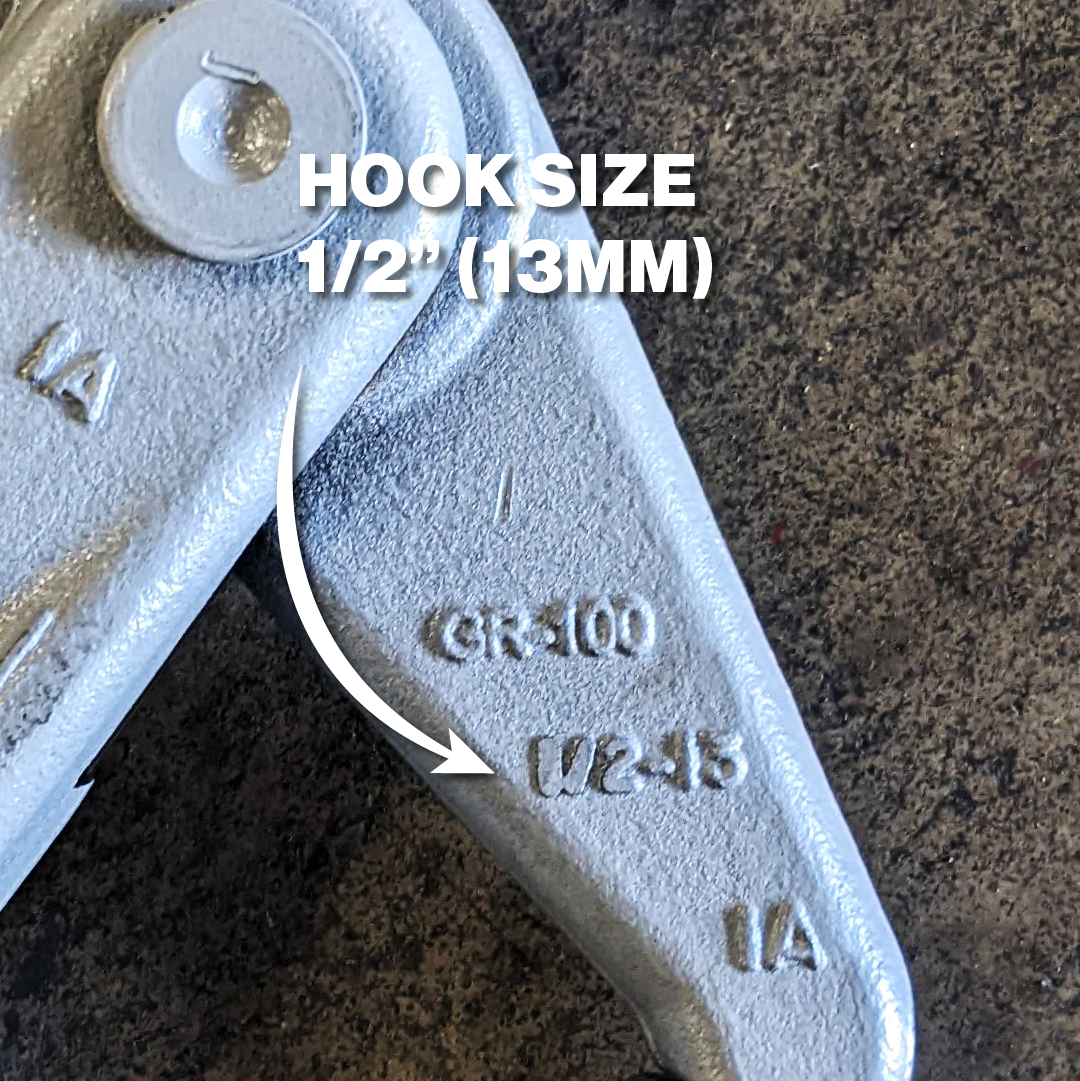

There's also a special code on Crosby hooks that tells where and when they were made. This keeps the hooks high quality and lets people check where they came from. It adds an extra layer of trust in the equipment for those using it.

How to Identify Crosby Hooks

To know if a Crosby hook is real, look closely at certain features and marks. You need to know the different kinds of Crosby hooks and what they're for. Also, seeing what shows a Crosby product is real is important.

Crosby hooks come in a few types, each with its own job. These are:

- Clevis sling hooks

- Eye grab hooks

- Swivel hooks

To spot a real Crosby hook, it helps to know what to look for. These are some key things to check:

- The Crosby name is often on the hook bowl's bottom.

- Hooks have colors that show their grade, making them easy to recognize.

- The Hook ID helps find the right latch kit size for a hook, making sure they fit together.

Checking if a hook is really Crosby means making sure the latches match perfectly. Think about how the hook is used, its details, size, and age.

In short, grasping how to identify Crosby hooks means focusing on special marks and standards. For tips on spotting real Crosby hooks, concentrate on the types, marks, and codes of genuine Crosby gear.

Conclusion

Knowing how to recognize Crosby hooks is key for safety in lifting jobs. Crosby marks their hooks uniquely. These markings help inspectors and riggers know a hook is real. They also help ensure safety fits strict guidelines.

It's crucial to check lifting gear often. Looking for signs of change, ensuring it's locked right, and staying within weight limits is vital. This way, lifting jobs stay safe and reliable.

By learning Crosby's high standards, experts keep Crosby hooks safe. These practices make work more efficient and safer. Following Crosby's hook features and checks avoids dangers. It also keeps Crosby gear working well.

Check out our online selection of in stock and ready to ship Crosby Hooks for sale you can buy online today. Bishop Lifting is a proud authorized dealer of Crosby Hooks and their products including Crosby Shackles.

Learn more about What Crobsy Shackles are made for from our recent article and post.

FAQ

What specific markings and codes help in Crosby hook identification?

Crosby hooks are easy to identify. Look for the Crosby name, which is on the hook's bowl. You'll also see product codes for tracking. The QUIC-CHECK® system shows if a hook is safe to use. Different colors show the hook's strength. Platinum is the strongest, gold is next, and red is for carbon steel.

What are the QUIC-CHECK® features on Crosby hooks and how do they help in Crosby hook inspection?

The QUIC-CHECK® system has marks that show if a hook is bent. Deformations can mean the hook is not safe. There are also marks showing the correct angle a hook can safely be used at. This helps people quickly check if a hook was used too hard.

How do the Crosby hook characteristics ensure safety in lifting operations?

Crosby hooks have built-in safety checks. These checks help users make sure the hooks are safe. By looking for these marks regularly, you can help avoid accidents. Making sure the hook is not too worn or damaged is key to safe lifting.

What are the benefits of identifying and using authentic Crosby hooks in lifting operations?

Using real Crosby hooks means you meet safety standards. Hooks that fit well and are not too worn are safer. They are strong because they are made with care.

How can one differentiate between different grades of Crosby hooks?

Different Crosby hooks are shown with different colors. Platinum is the top grade, gold is next, and red is standard. These colors help you quickly pick the right hook for the job.

Why is it crucial to follow Crosby hook safety guidelines and inspections?

Sticking to safety rules and checking hooks often cuts risks. This keeps lifting work safe and smooth. It's key to keep hooks in good shape with checks and care.

What types of hooks are included in the Crosby product range?

Crosby makes many hooks like the S-319, S-3316, S-320, and S-322 types. All of these are top-notch for various lifting jobs. They are strong and last a long time.

What makes Crosby hooks a preferred choice among rigging professionals?

Riggers love Crosby hooks because they are reliable. Crosby has a long history of making top-quality gear. Their hooks are built to last and go through tough testing.

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026

What Are the Four Basic Types of Turnbuckle End Fittings?

Dec 30th 2025

What Is a Turnbuckle Used for in Rigging?

Dec 23rd 2025

What’s the Best Material for Rigging?

Dec 18th 2025

What Is the 10-Foot Rule for Rigging?

Dec 15th 2025