Product Description

Sea Catch Toggle Release Mechanisms

Sea Catch Toggle Releases are precision-engineered for the controlled, safe release of a line or object under load. Built from aerospace-grade stainless steel and proven in harsh marine and industrial conditions, these mechanisms deliver dependable performance wherever safety, precision, and corrosion resistance are critical.

Important: Sea Catch devices are not designed or rated for lifting. They are intended solely for controlled release applications under load or no-load conditions.

Designed for use in towing, rescue, launch deployment, and special effects applications, Sea Catch units are available in capacities from 1 to 600 tons and support both on-load and off-load release. Each model uses a proven toggle linkage system—offering smooth operation, no springs, and simple maintenance.

Key Features

- Safe on-load and off-load release capability

- All-stainless steel construction for corrosion resistance

- Perpendicular or parallel release directions

- Hitch pin safety lock prevents inadvertent release

- Precision-cut components for smooth, low-friction action

- Compatible with standard shackles or clevis connections

- No springs or fragile components

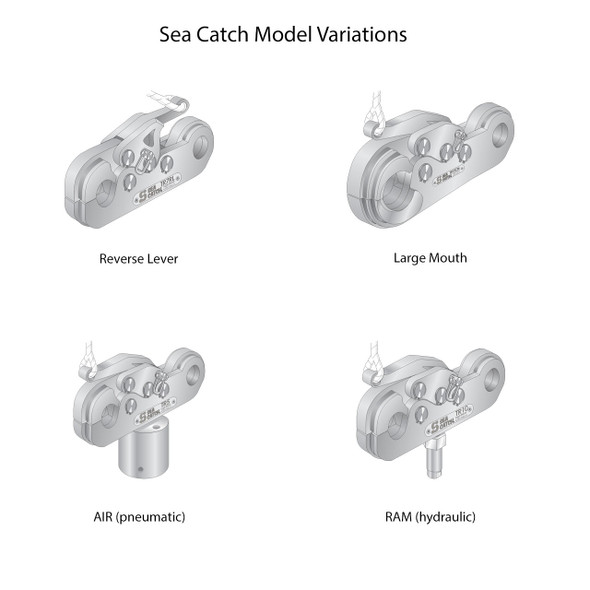

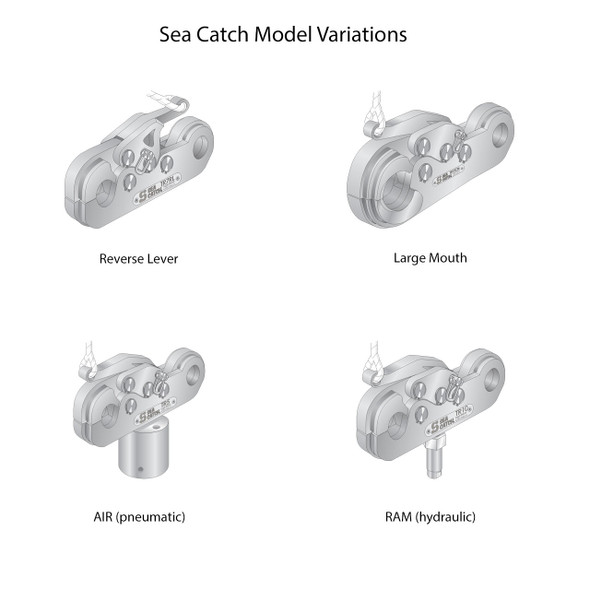

Release Method Options

Sea Catch mechanisms can be equipped with various activation methods to meet your operational requirements:

- Manual Release: Standard configuration using a lanyard or pull line to activate the release lever. Suitable for smaller models and general-purpose use.

- Pneumatic Release (AIR Models): Air cylinder activation allows remote operation using shop air at 60–100 PSI. Manual lanyard backup remains functional for safety redundancy.

- Hydraulic Release (RAM Models): Equipped with a hydraulic cylinder mounted below the device, the plunger pushes the toggle pin upward when pressurized, causing release. Manual release remains available as a backup. RAM units can be operated remotely via a single 1/4" hydraulic hose and are compatible with Enerpac® systems such as the PUD-1101B electric pump, an air-hydraulic foot pump, or the P-142 hand pump (up to 5,000 PSI maximum). Hydraulic pressure must be released prior to re-arming the device. Note: Enerpac cylinders are not corrosion-resistant and are not designed for submersion.

Special Model Options

- Reverse Lever (RL Models): The release lever is repositioned to allow side-access activation—ideal for tight or limited-access installations. Operators must always stand clear of any object being released under load.

- Large Mouth (LM Models): Features an enlarged jaw opening to accommodate webbing, straps, or synthetic line. Reinforced side plates help distribute load evenly and reduce chafing.

Applications

- Marine towing and recovery

- Rescue launch deployment

- Anchor and buoy release

- Payload and test platform systems

- Film, stage, and special effects rigging

Since 1994, Sea Catch release mechanisms have been trusted in more than 14 major industries worldwide—many units exceeding 5,000 release cycles and still in operation today.

Note: Sea Catch mechanisms are release devices only and are not intended for lifting or hoisting applications.

Specifications

Safety Notice

Although Bishop Lifting strives to manufacture and sell the highest quality rigging and safety gear, use of the gear is dangerous if not used correctly by competent trained professionals. Bishop Lifting disclaims any liability resulting from the misuse of its rigging and safety gear. Please take a moment to more thoroughly review our disclaimer.

Bishop Lifting rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Bishop Lifting disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Bishop Lifting should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.