What is rigging equipment?

Did you know that in the United States alone, rigging equipment plays a crucial role in numerous industries, facilitating the safe lifting and transportation of heavy loads?

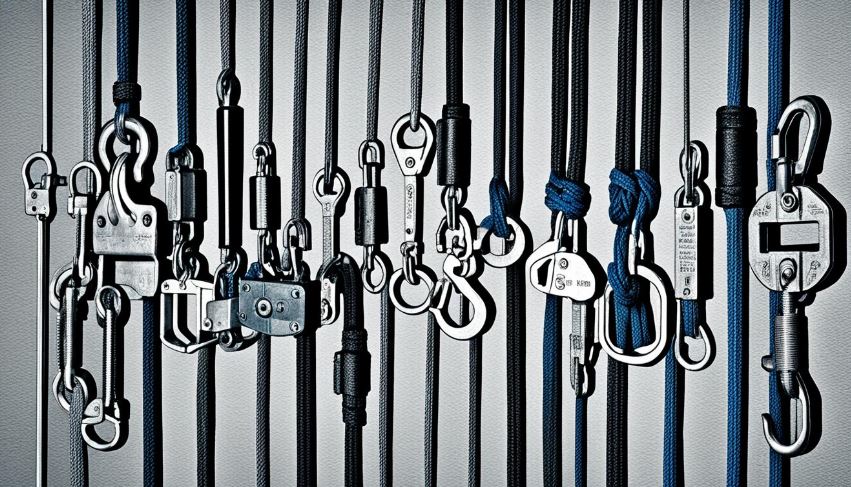

Rigging equipment, also known as lifting equipment or rigging gear, encompasses a wide range of tools and machinery specifically designed for lifting operations. From cranes and hoists to slings and hooks, each piece of equipment serves a unique purpose in ensuring efficient and secure lifting.

In this article, we will delve into the world of rigging equipment, exploring the different types of equipment used, their functions, and their importance in various industries. Whether you're a professional rigger or simply curious about this essential aspect of heavy lifting, join us as we uncover the fascinating world of rigging equipment.

Key Takeaways:

- Rigging equipment is essential for safe and efficient lifting operations.

- This equipment includes cranes, hoists, slings, hooks, and more.

- Each piece of rigging equipment serves a unique purpose in the lifting process.

- Rigging equipment plays a crucial role in various industries across the United States.

- Understanding different types of rigging equipment is important for both professionals and those interested in heavy lifting operations.

Distinguishing Lifting from Rigging

In the realm of heavy lifting, two key processes play integral roles: lifting and rigging. While these terms are often used interchangeably, it is important to understand the nuanced differences between them. Lifting refers to the action of raising or hoisting an object, while rigging encompasses the entire process of preparing, securing, and controlling the load for safe lifting operations.

Lifting Operations:

- Lifting is the direct act of raising or lowering heavy objects, typically using machinery such as cranes, hoists, or forklifts.

- Lifting operations focus on the physical movement of the load from one point to another.

- Lifting requires specialized equipment for the safe and efficient movement of heavy objects, including hooks, chains, slings, and lifting points.

Rigging Operations:

- Rigging encompasses the entire process of preparing the load for lifting, ensuring it is properly secured, controlled, and positioned.

- Rigging operations include tasks such as selecting the appropriate rigging equipment, calculating load weights, and designing rigging plans.

- Riggers are responsible for assessing load stability, managing load control systems, and ensuring compliance with safety regulations.

Understanding the distinction between lifting and rigging is crucial for proper planning and execution of heavy lifting operations. By recognizing the unique responsibilities and equipment associated with each process, industry professionals can ensure safe and efficient lifting activities.

What are the Rigging Equipment?

In rigging operations, a wide range of equipment is used to ensure safe and efficient lifting. Understanding the different types of rigging equipment is essential for riggers and operators alike. This section explores various tools and gear that are essential for rigging operations.

The types of rigging equipment include:

- Rigging Hooks: These hooks are designed to securely attach loads to lifting devices and are available in different sizes and configurations.

- Wire Ropes: Wire ropes are strong and durable cables that are used for lifting heavy loads. They are made of multiple strands of wire twisted together.

- Slings: Slings are flexible straps or chains that are used to support and lift loads. They come in various materials and configurations, such as chain slings, wire rope slings, and synthetic web slings.

- Pulleys and Blocks: Pulleys and blocks are used to change the direction of force and provide mechanical advantage in lifting operations.

- Eye Bolts: Eye bolts are bolting hardware with a looped head that provides a secure attachment point for lifting.

- Steel Nuts: Steel nuts are threaded fasteners used to secure bolts and other components in rigging applications.

- Turnbuckles: Turnbuckles are tensioning devices used to adjust the tension or length of rigging equipment.

- Spreader Bars: Spreader bars are lifting accessories that evenly distribute the load weight and maintain stability during lifting operations.

- Lifting Beams: Lifting beams are specialized devices that provide a stable lifting point for loads that cannot be lifted with conventional rigging equipment.

Each type of rigging equipment serves a specific purpose and function, contributing to the overall safety and effectiveness of rigging operations. It is crucial to select the appropriate equipment based on the specific lifting requirements and load characteristics.

Understanding Crane Rigging

In crane operations, rigging plays a crucial role in safely and efficiently lifting heavy loads. Understanding crane rigging and the specialized equipment used is essential for riggers and crane operators alike.

Crane rigging involves the process of preparing the load for lifting, securing it to the crane's hook, and ensuring its stability during operation. Rigging equipment designed specifically for crane operations is used to facilitate these tasks. This equipment is specially designed to withstand the high forces and unique requirements of crane lifting.

An important piece of rigging equipment used in crane operations is the rigging sling, which is used to safely secure and lift the load. Rigging slings come in various types, including wire rope slings, chain slings, and synthetic slings. These slings are designed to distribute the load weight evenly and reduce stress on the load and crane.

Additionally, rigging hooks are used to connect the load to the crane's lifting mechanism. These hooks feature a secure latch or latchless design to ensure proper attachment and prevent accidental release during lifting.

Other essential crane rigging equipment includes shackles, which are used to connect various rigging components, such as slings and hooks. Turnbuckles are used to adjust the tension in rigging systems, while eye bolts provide anchor points for attaching slings and hooks.

Furthermore, pulleys and blocks are used to change the direction of force in a rigging system, allowing for efficient load handling. These components allow the crane operator to position the load precisely and optimize the lifting process.

Crane rigging operations require careful planning and adherence to safety procedures. Rigging equipment must be inspected for any signs of damage or wear before each job. Proper training and compliance with industry regulations are vital to ensure the safety of personnel and the successful completion of crane lifting operations.

Key Responsibilities of a Crane Rigger

A crane rigger plays a vital role in ensuring safe and successful lifting operations. They are responsible for several crucial tasks that are essential for the smooth execution of rigging operations.

One of the key responsibilities of a crane rigger is to create a rigging plan. This involves carefully assessing the load to be lifted, determining the appropriate rigging equipment, and designing a plan that ensures optimal safety and efficiency. The rigging plan serves as a blueprint for the entire rigging operation, guiding the rigger and other team members throughout the process.

Worksite preparation is another crucial aspect of a crane rigger's responsibilities. This includes inspecting the worksite, identifying potential hazards, and ensuring that the area is clear and suitable for the lifting operation. The rigger must also assess the ground conditions to determine if any special precautions or additional equipment are required to ensure stability during the lift.

Proper machinery alignment is essential to maintain the stability and balance of the load during lifting. The crane rigger is responsible for precisely aligning all machinery involved in the rigging operation, including the crane, rigging equipment, and any other lifting accessories. This alignment ensures that the load is lifted safely and securely.

Load calculation is another critical responsibility of a crane rigger. They must accurately calculate the weight of the load to be lifted, considering factors such as the type of material, load dimensions, and any additional equipment or rigging accessories. This calculation helps determine the appropriate rigging equipment and ensures that the crane is set up and operated within its safe working load limits.

Movement coordination is a crucial aspect of a crane rigger's role. They must closely coordinate with the crane operator and other team members to ensure the precise movement and positioning of the load. Effective communication and coordination are essential to maintain safety and avoid any accidents or damage during the lifting operation.

In summary, a crane rigger plays a crucial role in rigging operations. Their responsibilities include creating a rigging plan, preparing the worksite, aligning machinery, calculating load weights, and coordinating the movement of the load. By fulfilling these responsibilities with expertise and precision, crane riggers ensure safe and efficient lifting operations.

Calculating Weights in Rigging Operations

In rigging operations, accurately calculating load weights is crucial for ensuring safe and efficient lifting. By determining load volume, employing methods for material weight determination, and utilizing industrial weight charts, riggers can assess and calculate weights with precision. Let's explore these steps in detail.

To begin, determining load volume involves assessing the dimensions of the load. Whether it's a solid object or a bulk material, understanding the volume is essential for accurate weight calculation. This can be achieved by measuring the length, width, and height of the load and considering any irregularities or variations in shape.

Next, methods for material weight determination come into play. Different materials have varying densities and weights, so it's vital to take this into account when calculating the overall load weight. Manufacturers and suppliers often provide the weight per unit volume or weight per unit length for common materials, which can serve as a useful reference.

Furthermore, industrial weight charts are invaluable tools for riggers. These charts provide weight conversions for various materials and configurations, including steel plates, beams, pipes, and more. By cross-referencing the load's dimensions and material type with the appropriate weight chart, riggers can obtain accurate weight values.

It's worth noting that load weights in rigging operations can be influenced by additional factors, such as moisture content, temperature, and other external elements. Therefore, it's important to account for these variables and make adjustments accordingly to ensure precise weight calculations.

By following these steps and utilizing the proper tools and references, riggers can accurately calculate load weights in rigging operations. This information allows for effective planning and execution of lifting operations, ensuring safety and efficiency.

Best Safety Practices in Rigging

Rigging operations involve handling heavy loads and require strict adherence to safety practices to prevent accidents and injuries. By implementing the following best safety practices, riggers can ensure safe and secure rigging operations.

- Rigging Gear Inspection: Regular inspection of rigging gear is crucial to identify any signs of wear, damage, or degradation. Inspect items such as slings, hooks, shackles, and lifting hardware for any defects before each use. Replace any damaged or worn-out gear immediately to maintain rigging safety.

- Consider Working Load Limit: Understanding the working load limit (WLL) of rigging equipment is essential for safe operations. The WLL indicates the maximum weight that the gear can safely handle. Always ensure that the load being lifted is within the WLL of the equipment being used. Exceeding the WLL can lead to failure and hazardous situations.

- Sling and Hitch Selection: The selection of the appropriate sling and hitch is crucial for load stability and rigging safety. Consider factors such as the weight and shape of the load, as well as the working environment, when choosing slings and hitches. Match the sling type (such as wire rope slings, chain slings, or synthetic slings) to the load requirements and ensure proper connection points.

By adhering to these best safety practices, riggers can significantly reduce the risk of accidents and ensure the safety of both the rigging crew and the load being lifted. Prioritizing rigging safety promotes efficient and successful operations in various industries.

Essential Rigging Hardware

In order to ensure safe and efficient rigging operations, it is crucial to use high-quality and reliable rigging hardware. These essential components play a vital role in supporting and securing loads during lifting operations. Let's take a closer look at some of the key rigging hardware used in various industries:

1. Anchor shackles: Anchor shackles are used to connect lifting slings, ropes, and chains to the load. They are designed to withstand heavy loads and provide a secure connection.

2. Turnbuckles: Turnbuckles are used to adjust the tension in wire ropes and cables. These versatile hardware components allow for fine-tuning and maintaining the proper tension during rigging operations.

3. Wire rope thimbles: Wire rope thimbles are used to protect wire ropes from wear and damage at connection points. They provide a smooth and durable surface for the wire rope to pass through, improving its longevity and safety.

4. Rigging hooks: Rigging hooks are essential for securely attaching loads to lifting devices such as cranes. These hooks are designed to handle high loads and come in various configurations to accommodate different rigging requirements.

By using the right rigging hardware, riggers can ensure the stability, safety, and integrity of the loads being lifted. It is important to choose hardware that meets industry standards and undergoes regular inspections and maintenance. With the proper rigging hardware in place, lifting operations can be conducted smoothly and with utmost safety.

Conclusion

In summary, understanding rigging equipment is essential for safe and efficient lifting operations. Throughout this article, we have explored the different types of rigging equipment and their functions. From rigging hooks and wire ropes to pulleys and blocks, each piece of equipment plays a crucial role in the rigging process.

To ensure a successful rigging operation, it is important to distinguish between lifting and rigging and understand the responsibilities of a crane rigger. Calculating load weights accurately and adhering to best safety practices are also crucial for maintaining a safe working environment.

By using essential rigging hardware, such as anchor shackles and turnbuckles, riggers can ensure the reliability and security of their equipment. It is important to remember that rigging equipment is not only vital for heavy lifting but also plays a significant role in a wide range of industries.

In conclusion, having a comprehensive understanding of rigging equipment and its proper use is key to successfully executing lifting operations. By applying the knowledge gained from this article and following safety guidelines, riggers can ensure the smooth and secure movement of heavy loads, prioritizing the well-being of both workers and equipment.

If you ever need the best pricing for rigging equipment you can buy easily online our site Lifting.com has everything you need that can be shipped directly to you.

FAQ

What is the difference between lifting and rigging?

Lifting refers to the process of raising or hoisting objects, while rigging encompasses the equipment and techniques used to secure and support those objects during lifting operations.

What are some common types of rigging equipment?

Common types of rigging equipment include rigging hooks, wire ropes, slings, pulleys and blocks, eye bolts, steel nuts, turnbuckles, spreader bars, and lifting beams.

How does crane rigging differ from other rigging operations?

Crane rigging specifically involves the use of cranes to lift and move heavy loads. It requires specialized equipment such as crane hooks, wire ropes, and rigging slings.

What are the key responsibilities of a crane rigger?

Crane riggers are responsible for creating a rigging plan, preparing the worksite, aligning machinery, calculating load weights, and coordinating movement during lifting operations.

How are load weights calculated in rigging operations?

Load weights are calculated by determining the load volume, using methods for material weight determination, and referencing industrial weight charts to accurately assess and calculate the weights.

What are some best safety practices in rigging?

Best safety practices in rigging include regularly inspecting rigging gear, considering working load limits, and properly selecting slings and hitches for the specific lifting operation.

What are some essential rigging hardware components?

Essential rigging hardware includes anchor shackles, turnbuckles, wire rope thimbles, and rigging hooks. These high-quality components ensure safe and efficient rigging operations.

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026

What Are the Four Basic Types of Turnbuckle End Fittings?

Dec 30th 2025

What Is a Turnbuckle Used for in Rigging?

Dec 23rd 2025

What’s the Best Material for Rigging?

Dec 18th 2025