What Are DuckBill Anchors Used For?

DuckBill Earth Anchors are trusted ground anchoring solutions used across the construction, landscaping, utility, and environmental sectors. Engineered for rapid deployment and high holding capacities—from 300 lbs to over 3,000 lbs—DuckBill anchors are ideal for securing trees, poles, erosion control systems, and lightweight structures.

Key Takeaways

- Secure outdoor items, structures, and erosion control systems

- Ideal for light to moderate loads in standard soil types

- Professional-grade holding capacity with fast installation

- Minimal soil disturbance, environmentally friendly

- Range of models available for different load and soil conditions

Understanding DuckBill Anchors: Design and Functionality

The Unique Design of DuckBill Anchors

DuckBill anchors feature a bill-shaped tip and steel shaft that penetrate and rotate into undisturbed soil during installation. Once tensioned, the anchor rotates horizontally and locks in place, creating a load-bearing plane beneath the surface.

How DuckBill Anchors Work

Installed using a drive rod and hammer or power tool, the anchor is driven to depth and then tensioned to rotate into a load-locked position. This simple, effective mechanism resists uplift and shear forces, making it suitable for structural anchoring, guying, and slope stabilization.

Types and Sizes of DuckBill Anchors

DuckBill anchors are available in several models, each designed for specific load capacities and applications. The main series include:

- 40-DB1: Holds up to 300 lbs – Ideal for light-duty tasks like landscaping, small tents, and garden structures.

- 68-DB1: Holds up to 1,100 lbs – Commonly used in light construction, signage, and medium-sized installations.

- 88-DB1: Holds up to 2,000 lbs – Suitable for utility poles, tree guying, and larger structural anchoring.

- 138-DB1: Holds 3,000 lbs and above – Designed for heavy-duty applications including erosion control, retaining structures, and commercial construction.

Each anchor type is engineered for easy installation and long-lasting performance in its intended use case.

Browse DuckBill anchor models on Lifting.com.

Common Applications of DuckBill Anchors

- Securing portable buildings and sheds

- Tree anchoring and stabilization

- Soil erosion and slope stabilization

- Anchoring signage, tents, and fencing

- Utility pole and pipeline support

Compliance with ANSI, OSHA, and ASME Standards

DuckBill anchors are not classified under specific ANSI or ASME designations. However, when used in industrial or commercial settings, contractors and engineers should ensure that their use aligns with applicable OSHA regulations for materials handling and ground anchoring, such as 1926 Subpart H.

These anchors are designed for applications like tethering, guying trees, utility poles, signage, and erosion control structures—not for personal fall protection systems. It is the responsibility of the installer to verify that anchor selection meets the structural and safety requirements of the specific project and jurisdiction.

Installation Process

- Drive the anchor into the soil using a drive rod and hammer or hydraulic tool

- Remove the rod and apply upward tension to rotate and lock the anchor

- Attach guy wires, cables, or straps as needed

This process creates minimal soil disturbance and requires no excavation or concrete.

Benefits of DuckBill Anchors

- Labor Efficiency: Fast, one-person installation

- Environmental Friendliness: No concrete, minimal site impact

- Reliability: Tested holding capacities under a variety of soils

Conclusion

DuckBill Earth Anchors deliver a high-strength, low-impact anchoring solution that’s ideal for professionals in construction, utilities, and landscaping. Their broad model range ensures the right product for your load and soil type, while their simple installation keeps your project efficient and compliant.

To find the right DuckBill anchor for your job, visit our collection here. Also, visit our website Lifting.com where we all of your rigging and lifting equipment supplies as well as Pewag Security Chains and Helical anchors as well.

FAQs

What is a DuckBill anchor used for?

DuckBill anchors are used to secure structures, trees, poles, signs, and erosion control systems in soil.

How do DuckBill anchors work?

They are driven into the ground, then rotated under tension to lock in place, resisting uplift and movement.

What are the benefits of using DuckBill anchors?

They are quick to install, environmentally friendly, and offer high load capacity in various soil types.

What sizes are available?

DuckBill anchors range from DB1 (300 lbs) to DB4 (3,000+ lbs), each suited for different applications and soil conditions.

Are DuckBill anchors compliant with OSHA or ASME standards?

While not directly regulated by ANSI or ASME, projects may require OSHA-compliant use depending on application. Always verify load and safety requirements.

Lifting vs. Rigging Equipment: What’s the Difference (and What You Actually Need)?

Feb 24th 2026

The Complete Buyer’s Guide to Overhead Cranes

Feb 13th 2026

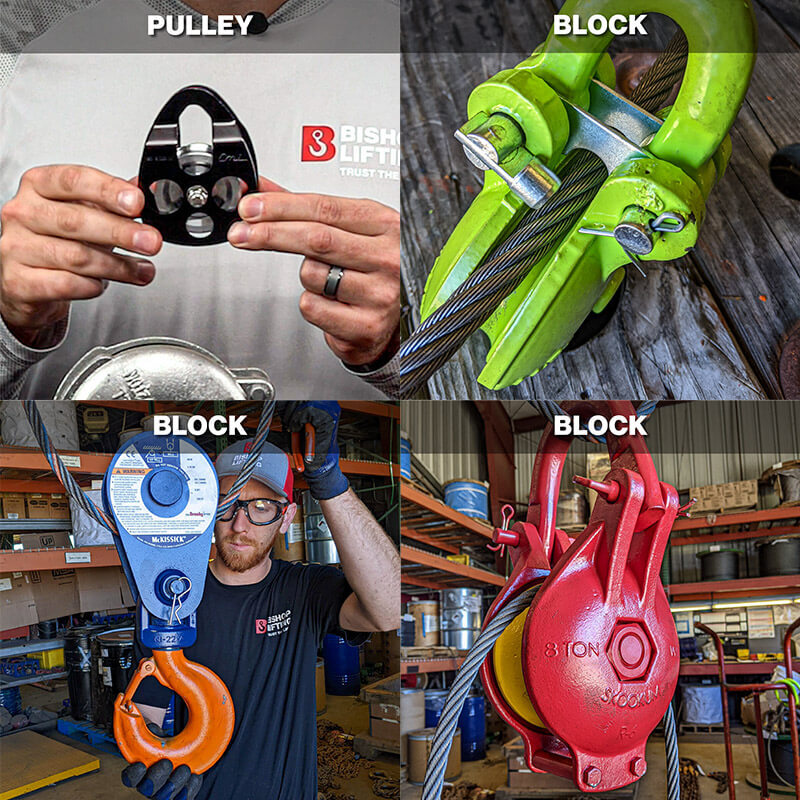

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026