Product Description

Crosby G-2130 Bolt Type Anchor Shackles

Crosby G-2130 Bolt Type Anchor Shackles are forged, quenched & tempered Grade 6 shackles with an alloy bolt, nut, and cotter pin for secure, semi-permanent rigging connections. Each unit is proof-tested, fatigue rated, and built to exceed industry standards for strength, consistency, and traceability. The G-series shackles feature the iconic Red Pin®—your mark of genuine Crosby quality.

Features

- Permanent Identification: Working Load Limit and Grade 6 markings shown on every shackle.

- Forged, Quenched & Tempered: High-strength alloy steel body with alloy bolts for maximum toughness and reliability.

- Finish Options: Hot-dip galvanized (G) stocked for corrosion resistance; self-colored (S) available by special order. 85 t, 120 t and 150 t shackles feature hot-dip galvanized bows with Dimetcoted® and red-painted bolts.

- Small Sizes: Sizes 3/8″ and below are mechanically galvanized.

- Fatigue Rated: Tested to 20 000 cycles at 1.5 × WLL (1/3 t – 55 t) for long service life.

- Temperature Range: Approved for use from −40 °F (−40 °C) to 400 °F (204 °C).

- Standards Compliance: Meets or exceeds ASME B30.26 requirements.

- Proof Testing: Shackles 85 metric tons and larger are individually proof-tested to 2 × WLL.

- Type Approval: Certified in accordance with ABS 2016 Steel Vessel Rules and ABS Guide for Certification of Lifting Appliances. Certificates available upon request (additional charges may apply).

- 3.1 Certification: Standard charpy and statistical proof test documentation available from 3.25 t to 25 t to DNV 2.7-1 and EN 13889.

- DNV Type Approved Models: Crosby 3.25 t through 25 t G-2130OC anchor shackles are type-approved to DNV Certification Notes 2.7-1 for Offshore Containers. These shackles are statistical proof- and impact-tested to 31 ft-lb (42 J) avg at −4 °F (−20 °C) with 3.1 test certification available on request.

- Optional Charpy Testing: All other G-2130 shackles can be charpy tested to 31 ft-lb (42 J) avg at −4 °F (−20 °C) upon request at time of order.

- Federal Specification Compliance: Meets RR-C-271H, Type IVA, Grade A, Class 3 (except contractor provisions).

- Genuine Crosby Quality: Look for the Red Pin® — the mark of authentic Crosby manufacture and performance.

Specifications

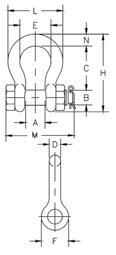

| Nominal Size (in) | WLL (t) | Weight (lb) | A (in) | B (in) | C (in) | D (in) | E (in) | F (in) | H (in) | L (in) | M (in) | N (in) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/16 | 0.33 | 0.06 | 0.38 | 0.25 | 0.88 | 0.19 | 0.60 | 0.56 | 1.47 | 0.98 | 1.29 | 0.19 |

| 1/4 | 0.5 | 0.11 | 0.47 | 0.31 | 1.13 | 0.25 | 0.78 | 0.61 | 1.84 | 1.28 | 1.56 | 0.25 |

| 5/16 | 0.75 | 0.22 | 0.53 | 0.38 | 1.22 | 0.31 | 0.84 | 0.75 | 2.09 | 1.47 | 1.82 | 0.31 |

| 3/8 | 1 | 0.33 | 0.66 | 0.44 | 1.44 | 0.38 | 1.03 | 0.91 | 2.49 | 1.78 | 2.17 | 0.38 |

| 7/16 | 1.5 | 0.49 | 0.75 | 0.50 | 1.69 | 0.44 | 1.16 | 1.06 | 2.91 | 2.03 | 2.51 | 0.44 |

| 1/2 | 2 | 0.79 | 0.81 | 0.64 | 1.88 | 0.50 | 1.31 | 1.19 | 3.28 | 2.31 | 2.80 | 0.50 |

| 5/8 | 3.25 | 1.68 | 1.06 | 0.77 | 2.38 | 0.63 | 1.69 | 1.50 | 4.19 | 2.94 | 3.56 | 0.69 |

| 3/4 | 4.75 | 2.72 | 1.25 | 0.89 | 2.81 | 0.75 | 2.00 | 1.81 | 4.97 | 3.50 | 4.15 | 0.81 |

| 7/8 | 6.5 | 3.95 | 1.44 | 1.02 | 3.31 | 0.88 | 2.28 | 2.09 | 5.83 | 4.03 | 4.82 | 0.97 |

| 1 | 8.5 | 5.66 | 1.69 | 1.15 | 3.75 | 1.00 | 2.69 | 2.38 | 6.56 | 4.69 | 5.39 | 1.06 |

| 1-1/8 | 9.5 | 8.27 | 1.81 | 1.25 | 4.25 | 1.13 | 2.91 | 2.69 | 7.47 | 5.16 | 5.90 | 1.25 |

| 1-1/4 | 12 | 11.71 | 2.03 | 1.40 | 4.69 | 1.29 | 3.25 | 3.00 | 8.25 | 5.75 | 6.69 | 1.38 |

| 1-3/8 | 13.5 | 15.83 | 2.25 | 1.53 | 5.22 | 1.42 | 3.63 | 3.31 | 9.16 | 6.38 | 7.21 | 1.50 |

| 1-1/2 | 17 | 19.00 | 2.38 | 1.66 | 5.75 | 1.53 | 3.88 | 3.63 | 10.00 | 6.88 | 7.73 | 1.62 |

| 1-3/4 | 25 | 33.91 | 2.88 | 2.04 | 7.00 | 1.84 | 5.00 | 4.19 | 12.34 | 8.80 | 9.68 | 2.25 |

| 2 | 35 | 52.25 | 3.25 | 2.30 | 7.75 | 2.08 | 5.75 | 4.81 | 13.68 | 10.15 | 10.81 | 2.40 |

| 2-1/2 | 55 | 98.25 | 4.13 | 2.80 | 10.50 | 2.71 | 7.25 | 5.69 | 17.90 | 12.75 | 13.58 | 3.13 |

| 3 | 85 | 154 | 5.00 | 3.30 | 13.00 | 3.12 | 7.88 | 6.50 | 21.50 | 14.62 | 15.13 | 3.62 |

| 3-1/2 | 120 | 265 | 5.25 | 3.76 | 14.63 | 3.62 | 9.00 | 8.00 | 24.88 | 17.02 | 17.00 | 4.38 |

| 4 | 150 | 338 | 5.50 | 4.26 | 14.50 | 4.00 | 10.00 | 9.00 | 25.68 | 18.00 | 17.75 | 4.56 |

Design Factor 6:1. Maximum Proof Load = 2× WLL. For side-loading reductions and application limits, see manufacturer warnings. Meets ASME B30.26. Operating range −40 °F to 400 °F.

Specifications

Safety Notice

Although Bishop Lifting strives to manufacture and sell the highest quality rigging and safety gear, use of the gear is dangerous if not used correctly by competent trained professionals. Bishop Lifting disclaims any liability resulting from the misuse of its rigging and safety gear. Please take a moment to more thoroughly review our disclaimer.

Bishop Lifting rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Bishop Lifting disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Bishop Lifting should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.