What are the most common tools used in rigging?

In industries where the safe and efficient handling of heavy loads is critical, rigging tools play an essential role. Whether you're in construction, maritime, logistics, or entertainment, having the right rigging equipment ensures operational success and regulatory compliance. Below, we’ll explore the most widely used rigging tools, their applications, and what to consider when choosing the best products for your needs.

1. Wire Ropes

Wire ropes are the cornerstone of most rigging setups. Known for their superior strength and flexibility, they are ideal for lifting, pulling, and securing loads. Galvanized and stainless steel options are available, including popular constructions such as 6x19 and 6x37. These ropes are widely used in cranes, hoists, and winches.

Browse Wire Ropes on Lifting.com

2. Slings

Slings are used to connect the lifting device (typically a crane or hoist) to the load. They come in several types, including:

- Wire Rope Slings: Durable and abrasion-resistant.

- Chain Slings: Best for high-heat environments.

- Synthetic Slings: Lightweight and non-damaging to delicate loads.

Choosing the right sling depends on your load type, weight, and lifting conditions.

3. Rigging Hooks

Hooks are essential for attaching slings or chains to loads. Options include clevis hooks, eye hooks, and self-locking hooks—all designed to meet rigorous safety standards. Be sure to choose hooks with appropriate load ratings and latching mechanisms to prevent accidents.

4. Shackles

Shackles serve as a connecting link between lifting devices and loads. They come in anchor, chain, and screw pin varieties. Look for shackles made from Grade 80 or higher steel and confirm their Working Load Limit (WLL).

5. Spreader Bars & Lift Beams

These tools help distribute weight more evenly, making them essential for lifting long or uneven loads. Spreader bars create a wider sling angle, reducing stress, while lift beams work well where headroom is limited.

Discover Lifting Beams & Spreader Bars

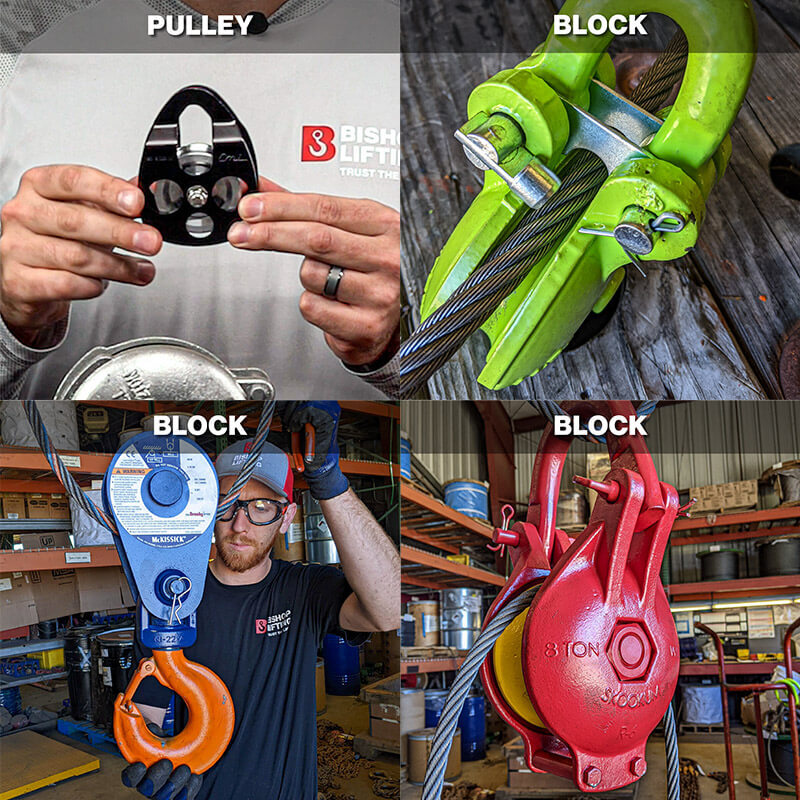

6. Pulleys and Blocks

Used to redirect force and multiply lifting power, pulleys and blocks are vital for complex rigging tasks. Options like snatch blocks, swivel blocks, and square blocks allow for versatility depending on your project’s load requirements.

7. Hoists

Manual, lever, and electric hoists allow you to lift and lower heavy loads safely. Features such as load limiters, dual-pawl systems, and sealed bearings increase reliability and safety.

8. Additional Accessories

Supporting gear like eye bolts, turnbuckles, load cells, rigging gloves, and safety harnesses help round out your rigging system, offering added safety, accuracy, and control.

Choosing the Right Rigging Equipment

To ensure safe and successful rigging operations, always consider:

- Load weight and center of gravity

- Working Load Limits (WLL) and safety factors

- Material compatibility and environmental exposure

- Compliance with OSHA and ASME standards

Conclusion

Investing in quality rigging tools is essential for operational safety and efficiency. At Lifting.com, we offer a wide selection of certified rigging hardware built to meet the demands of your industry.

Lifting vs. Rigging Equipment: What’s the Difference (and What You Actually Need)?

Feb 24th 2026

The Complete Buyer’s Guide to Overhead Cranes

Feb 13th 2026

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026