Which Wire Rope Construction Do You Need?

Wire rope constructions are defined by the number of individual wires and strands that make up the rope and the pattern in which they are laid. The most common types of wire rope constructions include 6x19, 6x36, and 7x19. Here's an overview of each:

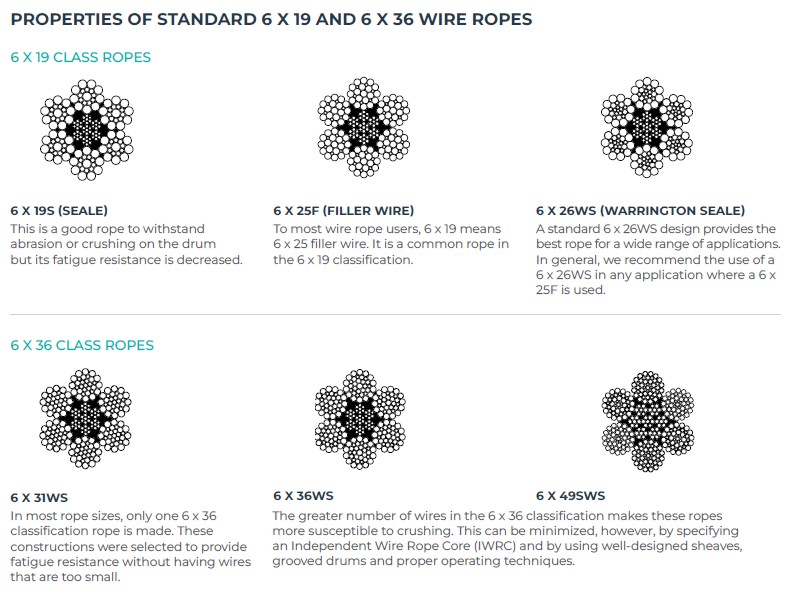

- 6x19 Wire Rope:

- Construction: 6x19 wire rope consists of six main strands in a classic 9-9-1 construction. That means each strand consists of 9 outer wires over 9 inner wires and 1 center wire. This particular construction is strong and abrasion-resistant, yet not highly flexible.

- Characteristics: This construction provides a good balance between flexibility and strength. It's often used in applications where the rope needs to bend and flex but still carry significant loads. It's popular for general-purpose lifting and hoisting.

- Most slings and chokers are built using a 6x19 class of wire rope.

- Popular variations include 6x25FW and 6x26WS. These constructions are technically different than true 6x19, yet perform very much the same for general rigging applications.

- Commonly sold in diameters from 1/4" - 1", sometimes larger.

- Available in "Bright" and Galvanized finishes.

- 6x36 Wire Rope:

- Construction: 6x36 wire rope is made up of six main strands, with each strand having 36 wires. The construction is similar to that of a 6x19 wire rope, yet there are significantly more (and smaller) wires in a 6x36 wire rope.

- Characteristics: The 6x36 construction offers improved flexibility compared to 6x19. This flexibility makes it suitable for applications that require the rope to navigate pulleys and sheaves while carrying heavy loads. It's commonly used in crane systems, winches, and elevator cables.

- While 6x36 wire rope carries the benefit of increased flexibility, it also carries the con of less resistance to abrasion. The outer wires are smaller and more prone to breakage and crushing.

- For large diameter slings, this is the preferred construction as stiffer constructions (such as 6x19) become difficult to work with.

- Similar to 6x19, there are varying types of 6x36 class wire rope, such as 6x37, that are functionally equivalent.

- Commonly sold in diameters from 3/8" - 1-1/2" and even larger.

- Available in "Bright" and Galvanized finishes.

- 7x19 Wire Rope:

- Construction: 7x19 wire rope consists of seven strands, each composed of 19 wires. This construction is known for its high flexibility and is composed of 6 outer strands wrapped around one inner strand.

- Characteristics: 7x19 wire rope is incredibly flexible, which makes it ideal for applications where bending and maneuvering are necessary. It's frequently used in control cables, guy lines, aircraft control surfaces, and other applications where precise control and flexibility are required.

- It comes in a galvanized finish and popular diameters range from 3/32" - 3/8".

- It is commonly used for winch lines and zip lines, especially in 5/16" and 3/8" diameters.

In all these constructions, the number of wires in each strand, the layout of the strands, and the materials used can vary depending on the specific requirements of the application. The choice of wire rope construction should be based on factors such as load capacity, flexibility, durability, and resistance to environmental factors like corrosion. It's important to consult with a wire rope expert to select the right construction for your specific needs. To that end, connect with Bishop Lifting today and let us help guide your search!

Below exceprt is from WireCo's Wire Rope User's Handbook, pg. 14.

What is a Capstan Winch?

Jul 7th 2025

Can Grade 70 Chain Be Used for Lifting?

Jun 28th 2025

What Is a Lifting Chain?

Jun 26th 2025

What is Considered Rigging Hardware?

Jun 20th 2025

What Tools Are Needed for Rigging?

Jun 18th 2025

What Equipment Does an Arborist Use?

Jun 13th 2025

What Is the Difference Between a Jib Crane and a Davit?

Jun 9th 2025

What Are the Types of Lifting Equipment?

May 30th 2025

How to Choose the Right Fall Protection Harness?

May 23rd 2025