What is the Difference Between Overhead and Gantry Cranes?

Material handling is essential across industries like manufacturing, construction, and logistics. Two common crane types—overhead and gantry—serve critical roles in lifting and transporting heavy loads, each offering unique benefits depending on their design and intended environment.

Overhead cranes are typically installed inside facilities and rely on the building’s structure for support, offering strong stability and integration with existing operations. Gantry cranes, by contrast, are freestanding systems with their own support frames—often on wheels or rails—providing unmatched flexibility and mobility.

Key Takeaways

- Overhead cranes use a facility’s internal structure for support.

- Gantry cranes are self-supported and often mobile.

- Structural differences influence installation, mobility, and application.

- Compliance with OSHA (29 CFR 1910.179), ASME B30.2, and ANSI standards is critical.

- Choosing the correct crane improves efficiency, safety, and long-term cost-effectiveness.

This guide includes practical comparisons, safety considerations, and use-case examples to help you choose the right crane solution. For crane systems that meet ANSI and OSHA standards, visit Lifting.com to explore overhead and gantry options.

Understanding Crane Systems in Modern Industry

Industries depend on crane systems to handle heavy loads and streamline production. Whether in manufacturing, construction, or logistics, efficient material movement is essential for safety and productivity.

The Role of Lifting Equipment in Material Handling

Cranes reduce manual labor, lower the risk of injury, and increase throughput. From large machines to bulky components, cranes are indispensable for safe and efficient transport in industrial settings.

Evolution of Crane Technology

Modern crane systems feature advanced control mechanisms, improved load distribution, and robust safety systems. Overhead and gantry cranes have evolved to meet specific operational requirements, improving both reliability and versatility.

Core Structural Distinctions

Overhead cranes are installed using a building’s internal structure. Gantry cranes have a freestanding frame that may include wheels or tracks, offering flexibility in placement and movement.

Support System Variations

Overhead cranes depend on existing structural supports. Gantry cranes stand independently, making them ideal for facilities lacking overhead infrastructure or for outdoor environments.

Overhead Cranes: Design and Components

- Bridge and Runway: The bridge spans the width of the facility and moves along fixed runways.

- Trolley and Hoist: These systems lift and move loads side-to-side and vertically.

- Control Mechanisms: Operators use pendant, radio remote, or automated controls for precision.

Gantry Cranes: Design and Components

- Leg Structures: A-frame legs provide stability and support for the bridge structure.

- Mobility: Equipped with wheels or rails, gantry cranes can move across work areas.

- Control Systems: Options include remote, pendant, or cabin controls depending on the use case.

Installation Requirements

Overhead cranes require strong building infrastructure for secure runway support. Gantry cranes only require a flat, stable surface, making them more versatile in terms of setup and relocation.

Operational Capabilities and Limitations

- Load Capacity: Overhead cranes typically lift heavier loads.

- Workspace: Gantry cranes are ideal for large or outdoor areas due to their mobility.

- Precision: Both can offer high precision depending on the control systems used.

Industry Applications

Overhead Cranes

- Manufacturing: Used for material flow, equipment installation, and assembly lines.

- Warehousing: Support pallet handling, inventory organization, and heavy lifting.

Gantry Cranes

- Shipyards & Ports: Load/unload containers and move ship components.

- Construction: Ideal for flexible outdoor material handling with quick setup.

Cost Analysis

- Initial Investment: Overhead cranes cost more due to infrastructure needs. Gantry cranes are more budget-friendly for open areas.

- Installation: Overhead requires structural integration; gantries are more plug-and-play.

- Long-Term: Maintenance, energy usage, and wear vary depending on crane type and use case.

Safety Considerations

Overhead cranes are governed by OSHA 1910.179 and ASME standards, requiring limit switches, anti-collision systems, and scheduled maintenance. Gantry cranes require ground-level stability checks and trained operators for mobile operation safety.

Maintenance and Longevity

- Preventative Maintenance: Regular inspections of hoists, trolleys, and electrical systems.

- Troubleshooting: Address misaligned tracks, faulty controls, or worn brake pads immediately to minimize downtime.

Conclusion: Selecting the Right Crane

Overhead cranes are best for fixed indoor applications with high load demands. Gantry cranes are ideal for versatile, mobile, or outdoor jobs. Evaluate your workspace, load requirements, and infrastructure to make the right choice.

For ANSI and OSHA-compliant crane systems, visit Lifting.com and explore a full range of overhead and gantry cranes in inventory you can easily buy online.

Frequently Asked Questions

What are the main differences between overhead and gantry cranes?

Overhead cranes rely on a building’s internal structure for support. Gantry cranes, on the other hand, use freestanding legs and are often mobile.

How do I choose between an overhead crane and a gantry crane for my facility?

Consider your workspace layout, load requirements, and whether the installation is indoors or outdoors. Overhead cranes are ideal for permanent indoor applications, while gantry cranes are more flexible and mobile.

What are the key components of an overhead crane?

Bridge, runway, trolley, hoist, and control systems—these work together to lift and transport loads efficiently across the workspace.

What are the advantages of using gantry cranes in shipyards and ports?

They offer high lifting capacity, easy mobility, and setup versatility, making them ideal for container handling and ship construction tasks.

How do the installation requirements differ between overhead and gantry cranes?

Overhead cranes require a pre-engineered building structure. Gantry cranes only need a flat, stable surface for their frame and movement path.

What safety considerations should be taken into account when operating overhead and gantry cranes?

Ensure compliance with OSHA and ASME standards, conduct regular maintenance, and provide operator training. Use anti-collision systems and follow safe load handling practices.

How do the operational capabilities of overhead and gantry cranes compare?

Overhead cranes typically offer greater lifting capacity and stability for fixed locations. Gantry cranes provide more flexibility for large or dynamic workspaces.

What are the cost implications of choosing between an overhead crane and a gantry crane?

Overhead cranes often have higher upfront costs due to structural installation. Gantry cranes are more cost-effective for temporary or outdoor operations.

What maintenance requirements should be considered for overhead and gantry cranes?

Regular inspections, lubrication, and replacement of worn parts are essential for both types. A preventative maintenance plan extends equipment lifespan and enhances safety.

How do I determine the load capacity of an overhead or gantry crane?

Capacity depends on design specs such as span, hoist type, and support structure. Always refer to the manufacturer's specifications and ASME load rating standards.

What are the distinguishing features of overhead and gantry cranes?

Overhead cranes have a bridge and runway tied into the building. Gantry cranes are freestanding, usually on wheels or tracks, and are easier to relocate.

How do overhead and gantry cranes compare in terms of speed and precision?

Both crane types can be fitted with advanced control systems. Overhead cranes are often more precise in fixed environments, while gantry cranes prioritize flexibility.

What are the key differences in the control systems of overhead and gantry cranes?

Overhead cranes often use pendant or radio remotes tied into facility systems. Gantry cranes may use similar remotes but can also include onboard cabin controls for large outdoor setups.

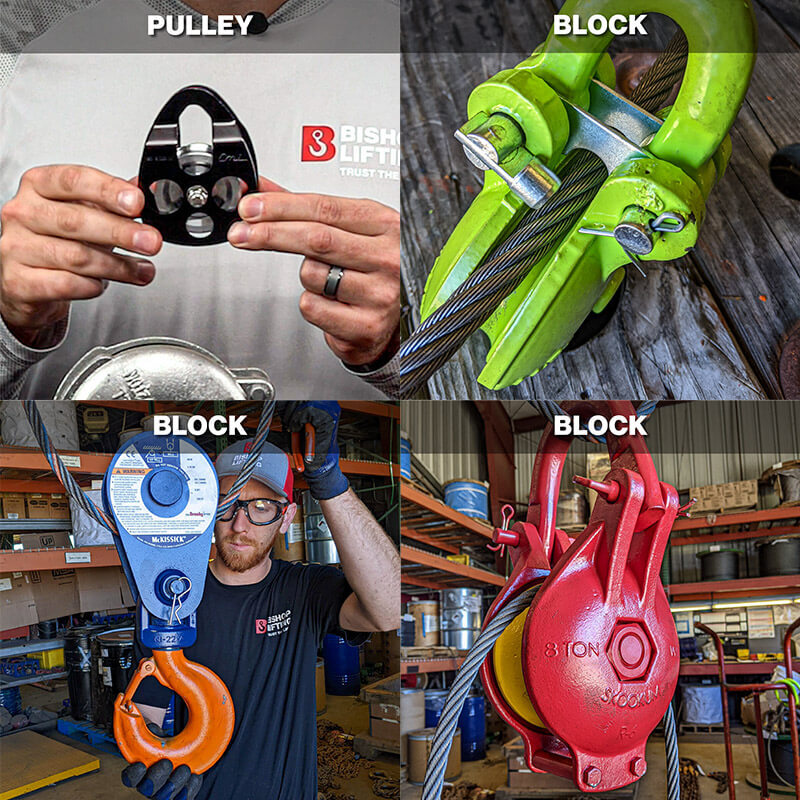

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026

What Are the Four Basic Types of Turnbuckle End Fittings?

Dec 30th 2025

What Is a Turnbuckle Used for in Rigging?

Dec 23rd 2025