What is better for a winch, rope, or cable?

Choosing between synthetic rope and steel cable for a winch depends on the winch type, the working environment, and specific application needs. Both options have their advantages—there’s no one-size-fits-all answer. Most winch manufacturers still offer traditional steel cable as standard but increasingly offer synthetic winch lines as an upgrade for specific advantages.

Understanding Winch Line Options

Winch lines generally fall into two categories:

- Steel Cable: Made from high-strength wire rope, usually galvanized or bright steel, designed for rugged environments where abrasion, heat, and sharp edges are a factor.

- Synthetic Rope: Typically made from HMPE fibers such as Dyneema® or Spectra®. Our primary offering, Hyper XII, delivers excellent strength-to-weight ratio and flexibility for demanding applications.

Advantages of Synthetic Winch Rope

- Lightweight: Easier to handle, reducing operator fatigue during winching operations.

- Safety: In the event of failure, synthetic rope stores far less kinetic energy, minimizing the risk of dangerous snapback injuries.

- Floatation: Synthetic lines float, making them ideal for marine, utility, and water recovery work.

- Field Repairable: Damage to synthetic lines can often be temporarily repaired on-site by braiding techniques.

Advantages of Steel Cable Winch Lines

- Durability: Better suited for extreme abrasion, sharp edges, and heat exposure found in rugged industrial or logging environments.

- Cost: Lower initial purchase cost compared to synthetic alternatives.

- Resistance to UV Degradation: Steel is unaffected by sun exposure, unlike unprotected synthetics.

Environmental and Application Considerations

- Rugged Terrain: Steel cable remains the best choice where there is frequent exposure to rocks, debris, or weld spatter.

- Weight-Sensitive Operations: Synthetic rope is ideal when minimizing line weight is crucial, such as in recovery, marine, or mobile service operations.

- Maintenance: Synthetic ropes are immune to rust but require UV protection. Steel cables must be regularly inspected for corrosion, broken wires, and kinks.

Which Winch Line Is Right for You?

There is no universal answer. The correct winch line depends on your job site demands, winch setup, and performance expectations. Hyper XII synthetic rope is an excellent upgrade where safety, weight reduction, and easy handling are priorities. Traditional steel cable remains a proven, durable choice for rugged and abrasive environments.

Conclusion

Both synthetic and steel winch lines have their place. Understand your winch specifications, operating environment, and job needs to select the right line. Choosing wisely helps improve safety, efficiency, and equipment longevity.

At Bishop Lifting, we stock a complete range of steel winch cables and Hyper XII synthetic winch lines ready to ship. Visit lifting.com to explore our full selection and order online today!

FAQ: Winch Line Selection

What is the main advantage of synthetic winch rope?

Synthetic winch rope, especially HMPE fibers like Hyper XII, offers superior handling, reduced weight, and safer failure characteristics with minimal snapback energy.

When is steel cable still preferred for winches?

Steel cable remains the best choice in highly abrasive environments, around sharp edges, or where high heat exposure is expected. It's durable and proven in rugged field conditions.

How does Hyper XII compare to traditional synthetic ropes?

Hyper XII is engineered for maximum strength-to-weight ratio, excellent abrasion resistance, and easier handling, making it ideal for industrial and recovery applications.

Can synthetic winch lines be repaired in the field?

Yes. Damaged synthetic ropes can often be temporarily repaired with proper braiding techniques. However, any repaired line should be inspected and replaced if integrity is compromised.

What environmental factors affect winch line selection?

UV exposure, moisture, temperature extremes, and contact with abrasive surfaces all influence winch line longevity. Synthetic lines resist water and rot; steel cables resist UV but can corrode without proper maintenance.

Is synthetic rope or steel cable more cost-effective over time?

Synthetic rope has a higher upfront cost but may reduce handling injuries, lower maintenance, and offer longer service life in specific applications. Steel cable costs less initially but demands regular inspections and care.

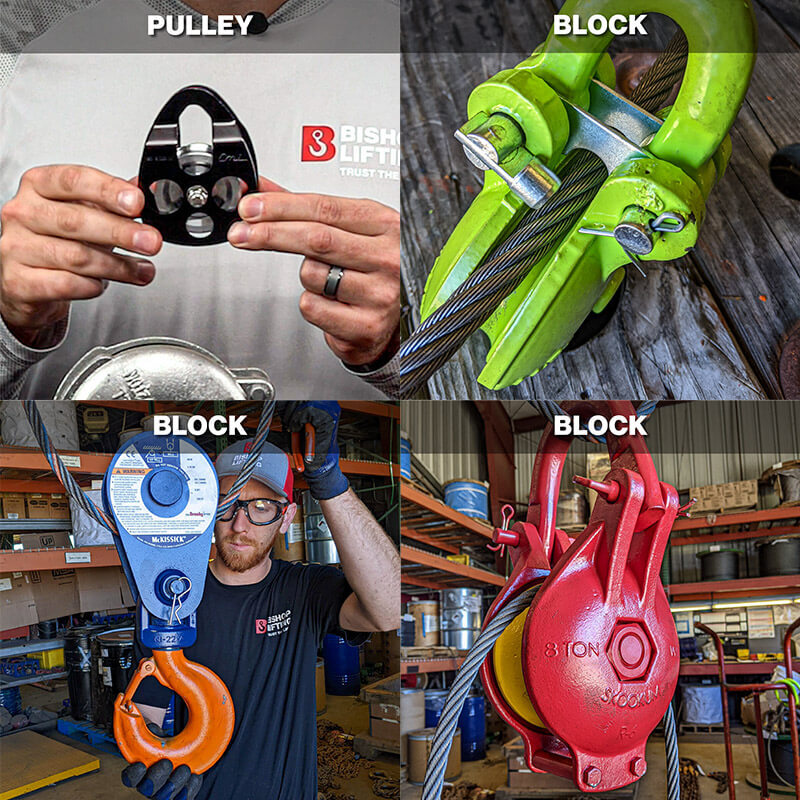

Which Pulley Can Lift Heavy Loads?

Feb 11th 2026

When Should a Spreader Bar Be Used for Lifting?

Feb 3rd 2026

How to Use a Snatch Block Safely (Step-by-Step for Rigging & Pulling)

Jan 30th 2026

What Is the “New” OSHA Standard for Fall Protection?

Jan 27th 2026

The 3 Main Types of Shackles (and How to Choose the Right One)

Jan 19th 2026

How to Secure a Synthetic Winch Rope to a Winch (Correctly & Safely)

Jan 12th 2026

Which Shackle Is Most Commonly Used in Rigging?

Jan 5th 2026

What Are the Four Basic Types of Turnbuckle End Fittings?

Dec 30th 2025

What Is a Turnbuckle Used for in Rigging?

Dec 23rd 2025