Product Description

AMH Weld-On Bucket Hooks – Grade 80 Alloy Steel

AMH Weld-On Bucket Hooks provide a strong, reliable lifting point when permanently attached to equipment such as buckets, blades, and booms. Forged from high-strength Grade 80 alloy steel, these hooks are ideal for connecting chain, wire rope, or synthetic slings in lifting or pulling applications. Each hook comes with an integrated safety latch and is fully compliant with ASTM A952/A952M-2 and ASME B30.10 standards.

Key Features:

- Made from Grade 80 alloy steel for strength and durability

- Weld-on design offers a permanent lifting or pulling point on heavy equipment

- Compatible with chain, wire rope, or web slings

- Safety latch included on every hook; replacement latches also available

- Meets ASTM A952/A952M-2 and ASME B30.10 requirements

- Warning: Never exceed the rated working load limit (WLL). Do not use for lifting people or over people.

Size & Capacity Range:

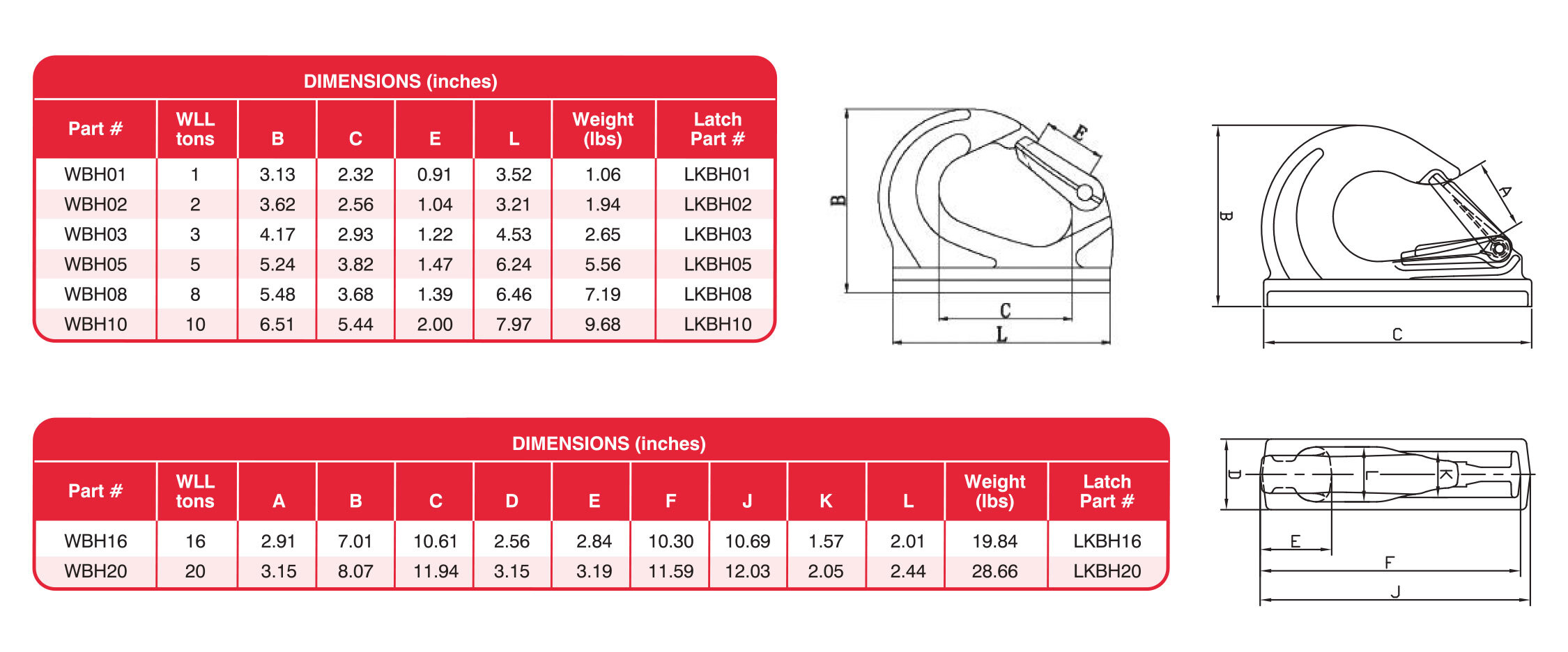

Available in capacities from 1 ton to 20 tons, these hooks fit a wide range of equipment and applications. Hook body sizes and profiles vary accordingly, with compact models for light-duty work and large-bodied hooks for high-capacity jobs.

Note: Hooks must be welded by qualified personnel following proper welding procedures. Always inspect before use.

Specifications

Safety Notice

Although Bishop Lifting strives to manufacture and sell the highest quality rigging and safety gear, use of the gear is dangerous if not used correctly by competent trained professionals. Bishop Lifting disclaims any liability resulting from the misuse of its rigging and safety gear. Please take a moment to more thoroughly review our disclaimer.

Bishop Lifting rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Bishop Lifting disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Bishop Lifting should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.