Product Description

Heavy-Duty Performance Without the Premium Price – Forged Imported Wire Rope Clips

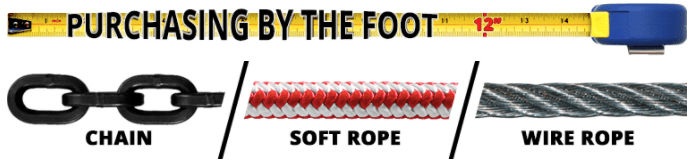

Our forged imported wire rope clips are hot dip galvanized for superior corrosion resistance and long service life. Built to secure wire rope terminations in a wide range of non-lifting applications, these heavy-duty clips deliver strength and reliability without the name-brand price tag. Available in sizes from 1/8" to 1-1/2", they provide comparable specs at a fraction of the cost thanks to imported manufacturing.

Ideal for fencing, guying, utility rigging, and general cable assemblies, these clips are forged for durability and finished to withstand rugged outdoor and industrial environments. If you don’t require a U.S.-made or name-brand product, these clips are a smart, cost-effective choice.

Key Features:

- Forged construction: Drop-forged for heavy-duty strength and durability

- Hot dip galvanized finish: Provides superior corrosion resistance in outdoor and marine environments

- Wide size range: From 1/8" up to 1-1/2" to fit various cable diameters

- U-bolt with hex nuts: Clamps securely over the dead end of the rope

- Affordable and dependable: Comparable performance to premium models at a lower cost

Important Safety Note:

Not for overhead lifting. While these clips are heavy-duty and forged for strength, no wire rope clip should be used in overhead lifting applications. Always follow proper installation guidelines and torque specifications.

Common Applications:

- Wire rope terminations (non-lifting)

- Fencing and barrier cable systems

- Guy lines and structural bracing

- Utility rigging and marine use

- Temporary or semi-permanent cable assemblies

Strong. Affordable. Easy to Use.

For reliable, heavy-duty cable terminations without the name-brand markup, our forged imported wire rope clips are a trusted solution. Choose from a full range of sizes and follow the installation steps below for secure, long-lasting results.

How to Install Wire Rope Clips:

- Turn back the specified amount of rope from the thimble or loop. Place the first clip one base-width from the dead end. Position the U-bolt over the dead end of the rope, with the saddle on the live end. Tighten nuts evenly, alternating from one to the other, until reaching recommended torque.

- If using two clips, place the second clip as close to the loop or thimble as possible. Tighten nuts evenly and alternately to the recommended torque.

- If using more than two clips, apply the second clip near the loop as above, but only finger-tighten. Add the remaining clips evenly spaced between the first two. Once positioned, tighten all nuts evenly, alternating between sides, to the specified torque.

- Apply initial load equal to the expected working load. Inspect the assembly to ensure clips are properly spaced and oriented. Retighten all nuts to the recommended torque to ensure secure installation.

Specifications

Safety Notice

Although Bishop Lifting strives to manufacture and sell the highest quality rigging and safety gear, use of the gear is dangerous if not used correctly by competent trained professionals. Bishop Lifting disclaims any liability resulting from the misuse of its rigging and safety gear. Please take a moment to more thoroughly review our disclaimer.

Bishop Lifting rigging and safety gear is only intended to be used by competent trained professionals. Misuse of the rigging and safety gear can result in serious injury up to and including loss of life. As such, Bishop Lifting disclaims liability for any misuse or incorrect product selection by our customers.

Rigging and safety gear purchased from Bishop Lifting should be used in strict accordance with all industry and OSHA standards. At no time should rigging or safety gear be used beyond its certified load ratings (aka Working Load Limits). Normal wear and tear should be expected with use of rigging and safety gear; therefore, all gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used.